873

FX3G/FX3U/FX3UC Series Programmable Controllers

Programming Manual - Basic & Applied Instruction Edition

38 Error Check Method and Error Code List

38.1 States and Colors of LEDs PLC Operation Status

31

FNC275-FNC279

Data

Transfer 3

32

FNC280-FNC289

High Speed

Processing 2

33

FNC290-FNC299

Extension File

Register

34

FNC300-FNC305

FX

3U

-CF-ADP

35

SFC•STL

Programming

36

Interrupt

Function

37

Special Device

38

Error Code

A

Version Up

Information

B

Execution Times

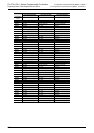

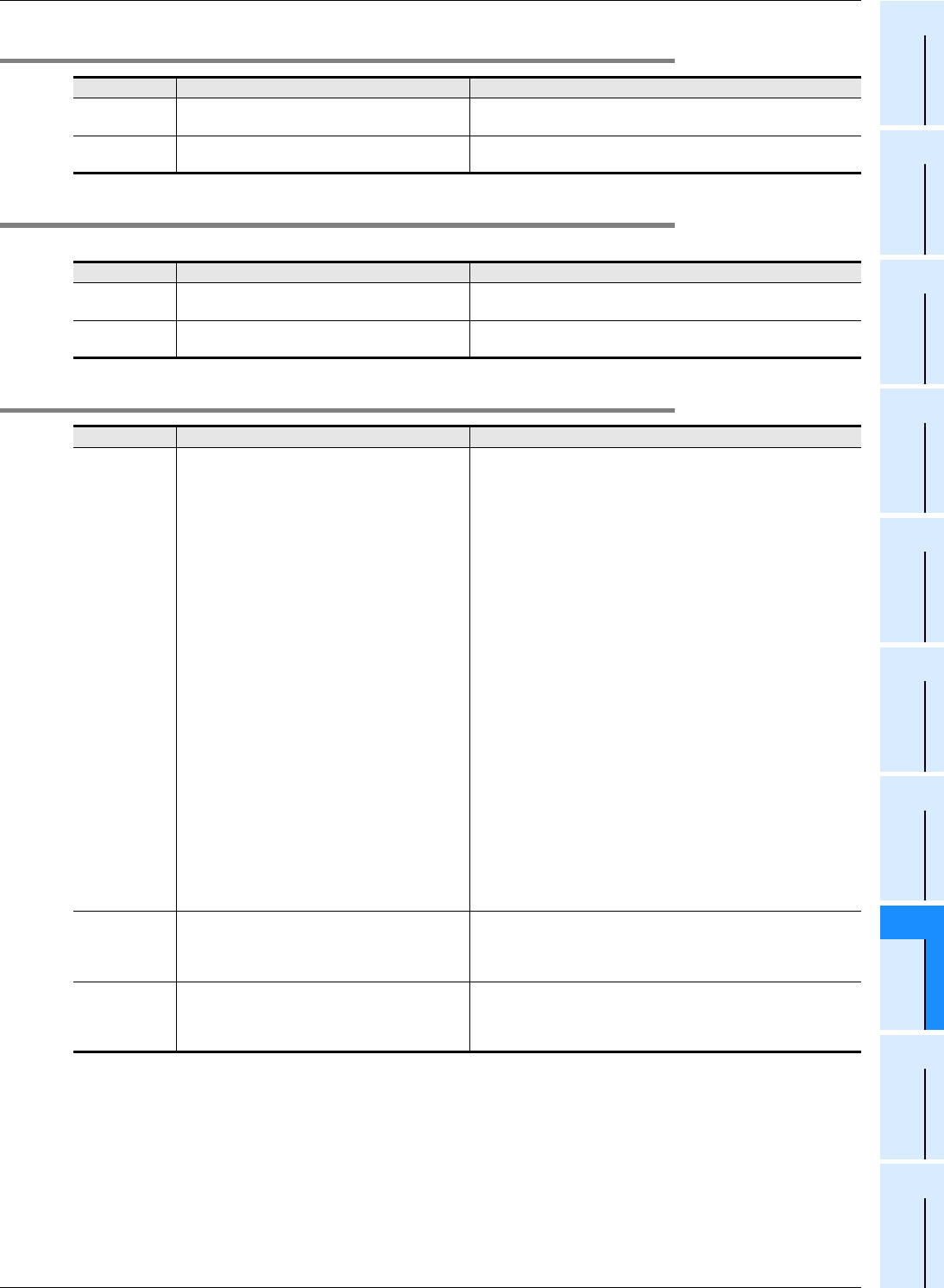

38.1.3 BATT (BAT) LED [lit or unlit] [FX3U/FX3UC]

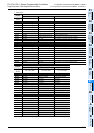

38.1.4 ALM LED [lit or unlit] [FX3G]

This LED is valid when the optional battery is installed and the battery mode is selected using a parameter.

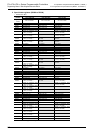

38.1.5 ERROR (ERR) LED [lit, flickering or unlit] [FX3G/FX3U/FX3UC]

LED status PLC status Action

Lit The battery voltage is low.

Replace the battery as soon as possible.

(Refer to FX

3U/FX3UC Hardware edition.)

Unlit

The battery voltage exceeds the value set in

D8006.

The battery is normal.

LED status PLC status Action

Lit The battery voltage is low.

Replace the battery as soon as possible.

(Refer to FX

3G Hardware edition.)

Unlit

The battery voltage exceeds the value set in

D8006.

The battery is normal.

LED status PLC status Action

Lit

A watchdog timer error has occurred, or

the hardware of the PLC may be

damaged.

1) Change the PLC mode to STOP, and turn ON the PLC power

again.

When the ERROR (ERR) LED is off, a watchdog timer error

occurred. Take one of the following actions:

- Review the program, and make sure that the maximum

value (D8012) of the scan time is not larger than the set

value (D8000) of the watchdog timer.

- Make sure that an input used for input interrupt or pulse

catch does not abnormally turn ON and OFF several times

in one scan time.

- Make sure that the frequency of the pulse (duty: 50%) input

to a high speed counter is within the specifications range.

- Adding WDT instruction

Use two or more WDT instructions in a program so that the

watchdog timer is reset several times in one scan time.

- Change the set value of the watchdog timer

Change the set value (D8000) of the watchdog timer in a

program so that it is larger than the maximum value (D8012)

of the scan time.

2) Remove the PLC, and connect another power supply to the

PLC.

If the ERROR (ERR) LED is off, the cause of the error may be

noise. Examine the following action:

- Check the wiring for grounding, and then review the wiring

route and installation location.

- Add a noise filter in the power line.

3) If the ERROR (ERR) LED is not off even after the step 1) or 2),

consult a Mitsubishi Electric Distributor.

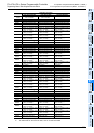

Flickering

Either of the following errors occur in PLC:

• Parameter error

• Syntax error

• Circuit error

Execute PLC diagnostics and program check by programming tool.

For instructions, refer to Section 38.4.

Unlit Error which stops PLC has not occurred.

If PLC operation is a failure, execute the PLC diagnostics or

program check by programming tool.

An I/O configuration error, serial communication error, or operation

error may occur.