853

FX3G/FX3U/FX3UC Series Programmable Controllers

Programming Manual - Basic & Applied Instruction Edition

37 Operation of Special Devices (M8000 -, D8000 -)

37.2 Supplement of Special Devices (M8000 - and D8000 -)

31

FNC275-FNC279

Data

Transfer 3

32

FNC280-FNC289

High Speed

Processing 2

33

FNC290-FNC299

Extension File

Register

34

FNC300-FNC305

FX

3U

-CF-ADP

35

SFC•STL

Programming

36

Interrupt

Function

37

Special Device

38

Error Code

A

Version Up

Information

B

Execution Times

37.2.2 Watchdog timer [D8000]

The watchdog timer monitors the operation (scan) time of the PLC. When the operation is not completed within the

specified time, ERROR (ERR) LED light turns on and all outputs are turned OFF.

When the power is initially turned ON, "200 ms" is transferred from the system to D8000 as the default value. For

executing a program beyond 200 ms, the contents of D8000 must be changed by the user program.

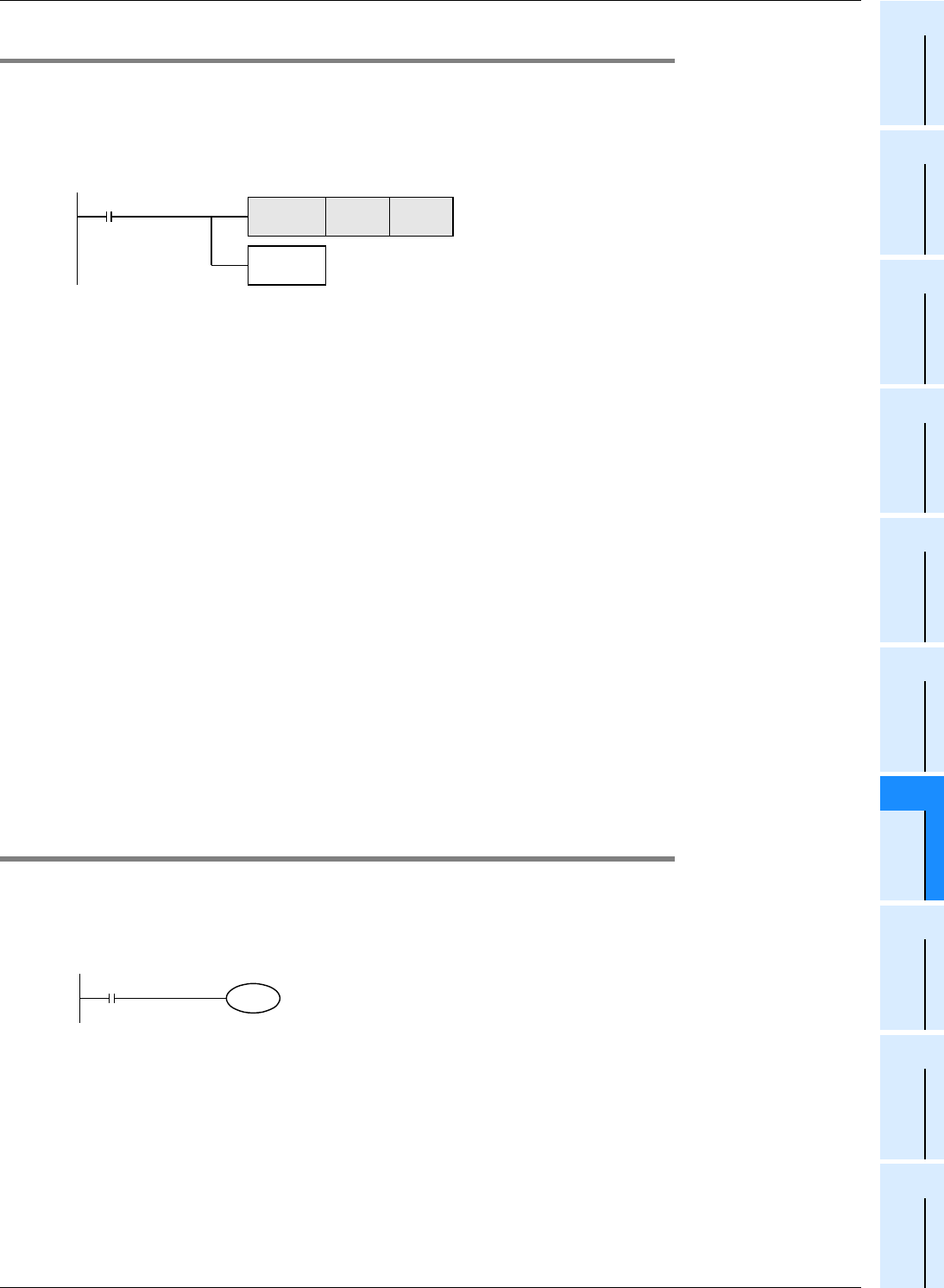

1. Example program

2. When a watchdog timer error occurs

A watchdog timer error may occur in the following cases. Add the above program to somewhere near the first step or

adjust the number of execution FROM/TO instructions at the same scan.

1) When using many special function units/blocks

When many special function units/blocks (such as positioning, cam switches, link and analog) are used, buffer

memory initial setting time becomes long at turning on the PLC, thus extending the operation time and allowing

the possibility for a watchdog timer error to occur.

2) When executing many FROM/TO instructions at the same time

When many FROM/TO instructions are executed or when many buffer memories are transferred, it extends the

scan time, and a watchdog timer error may occur.

3) When using many high speed counters (software counters)

When many high speed counters are programmed and high frequency is counted at the same time, it extends the

scan time, and a watchdog timer error may occur.

3. How to reset the watchdog timer

The watchdog timer can be reset in the middle of a sequence program using WDT (FNC 07) instruction.

It is recommended to reset the watchdog timer by WDT (FNC 07) instruction when the scan time of a particular

sequence program is extended or when many special function units/blocks are connected.

→ For WDT (FNC 07) instruction, refer to Section 8.8.

4. Cautions on changing the watchdog timer

The watchdog timer time can be set to a maximum of 32767 ms. However, CPU error detection is delayed when the

watchdog timer time is extended.

It is recommended to use the default value (200 ms) when no problems are to be expected in operation.

37.2.3 Battery voltage low detection [M8005 and M8006]

This special device detects low voltage in the lithium battery for memory backup.

In FX

3U/FX3UC PLCs, the BATT (BAT) LED turns ON when the PLC detects low battery voltage.

In FX

3G PLCs, the ALM LED indicator turns ON when the PLC detects low battery voltage if the optional battery is

installed and the battery mode is selected by the parameter setting.

Use the following program to notify low battery voltage to the outside.

M8002

Initial pulse

FNC 12

MOV

K300 D8000

FNC 07

WDT

Setting value of watchdog timer is set to "300 ms."0

The watchdog timer

When WDT (FNC 07) instruction is not programmed, the

value stored in D8000 is not valid until END processing.

M8005

Battery

voltage low

"Battery voltage low"

Y001

M8006 latches the battery voltage low.

0