389

FX3G/FX3U/FX3UC Series Programmable Controllers

Programming Manual - Basic & Applied Instruction Edition

14 Handy Instruction – FNC 60 to FNC 69

14.1 FNC 60 – IST / Initial State

11

FNC30-FNC39

Rotation and

Shift

12

FNC40-FNC49

Data Operation

13

FNC50-FNC59

High Speed

Processing

14

FMC60-FNC69

Handy

Instruction

15

FNC70-FNC79

External FX I/O

Device

16

FNC80-FNC89

External FX

Device

17

FNC100-FNC109

Data

Transfer 2

18

FNC110-FNC139

Floating Point

19

FNC140-FNC149

Data

Operation 2

20

FNC150-FNC159

Positioning

Control

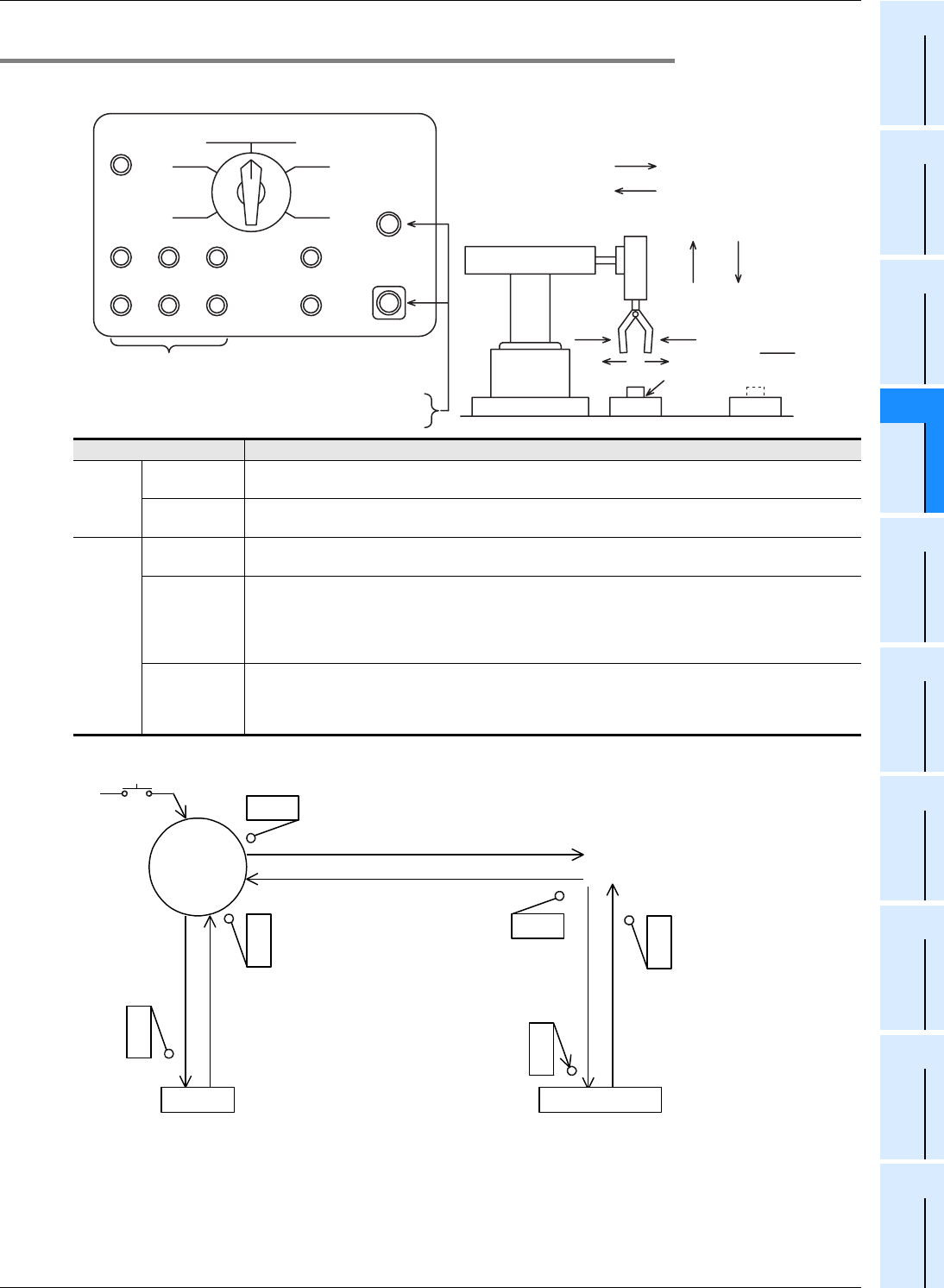

14.1.2 Example of IST instruction introduction (example of workpiece transfer mechanism)

1. Operation mode

2. Transfer mechanism

The upper left position is regarded as the zero point. The machine transfers a workpiece from the left to the right in the

order "moving down → clamping → moving up → rightward travel → moving down → unclamping → moving up →

leftward travel."

Double-solenoid type solenoid valves (with two inputs for driving and non-driving) are adopted for moving down,

moving up, leftward travel and rightward travel. Single type solenoid valves (which operate only while the power is

ON) are adopted for clamping.

Operation mode Contents of operation

Manual

mode

Individual

operation mode

Each load is turned ON and OFF by an individual pushbutton switch.

Zero return

operation mode

When the pushbutton switch for zero return is pressed, the machine automatically returns to the zero point.

Auto-

matic

mode

Stepping

operation mode

Every time the start button is pressed, the machine performs one process.

Cycle operation

mode

When the start button is pressed while the machine is located at the zero point, the machine performs one

cycle of automatic operation and stops at the zero point.

If the stop button is pressed in the middle of one cycle, the machine stops immediately. When the start

button is pressed after that, the machine performs the continuous operation from the last position, and

automatically stops at the zero point.

Continuous

operation mode

When the start button is pressed while the machine is located at the zero point, the machine starts

continuous operation.

When the stop button is pressed, the machine finishes the current cycle until the zero point, and then stops

at the zero point.

Unclamping Y001

Pushbutton switches for the external circuit to

turn ON and OFF the load power supply

X025

X021

X020

X022

X023

X024

Start X 026

Stop X027

X005 X006 X007

X010 X011 X012

PB PB PB

PB PB PB

PB

PB

PB

PB

PB

Zero return

Zero return

operation mode

Stepping

operation

Individual

operation mode

Moving up

Leftward

travel

Unclamping

Moving down

Rightward

travel

Clamping

Continuous

operation mode

Cycle

operation mode

Power supply

Emergency stop

Pushbutton switches for individual operations

of the robot hand shown in the figure on the right

Left limit X004

Y004

Y003

Rightward Right limit X003

Leftward

Y002 Y000

Upper

limit X002

Moving down

Moving

up

Clamping Y001

Workpiece

Point A Point B

Mechanism for transferring a workpiece from the

point A to the point B using the robot hand

Lower

limit X001

Zero point

Left limit X004

Start

X026

Upper limit X002

Clamping

Lower

limit

X001

(1) Moving

down

Y000

(3) Moving up

Y002

(2) Clamping

Y001 ON

Upper

limit

X002

Unclamping

Lower

limit

X001

(1) Moving down

Y000

(7) Moving up

Y002

(6) Unclamping

Y001 OFF

Right limit

X003

(4) Rightward Y003

(8) Leftward Y004

What is the zero point condition?

Upper limit X002 is ON, left limit

X004 is ON and unclamping Y001

is OFF.