Appendix - 80

MELSEC-Q

APPENDICES

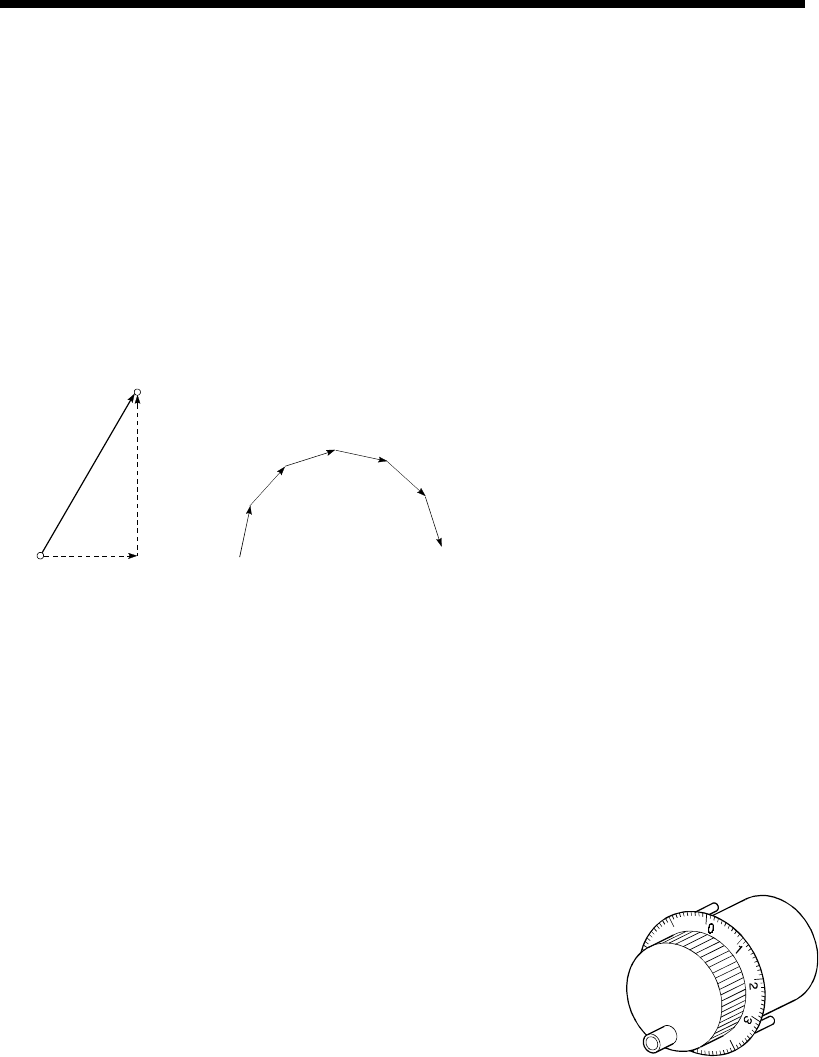

LINEAR INTERPOLATION

This automatic operation simultaneously

operates two motors for the latitudinal (X) feed

and longitudinal (Y) feed to move a target in a

diagonal line for positioning. Three or four

motors can also be operated simultaneously.

The QD75 combines the operation of axis 1

through 4 for the linear interpolation. The same

positioning data No. must be used for the

setting. Refer to the term "INTERPOLATION

OPERATION".

No.9

No.8

No.1

2

3

4

5

6

7

Longitudinal

feed

Latitudinal feed

LOAD INERTIA RATIO

GDL

2

/GDM

2

Refer to "GD

2

".

LOW-INERTIA MOTOR

This is a motor used when frequent

acceleration/deceleration is repeated. Low-

inertia motors are longitudinally longer, to

decrease the rotor diameter and cover the

torque. This enables their inertia moment to be

reduced up to 1/3 that of standard motors. The

ideal load inertia ratio is 1 or less.

M CODE (Machine Code)

These are sub functions that interlock with the

positioning operation to replace drills, tighten

and loosen clamps, raise and lower welding

electrodes, display various data, etc.

Either of two modes can be entered when the

machine code turns ON: AFTER or WITH.

The machine does not move to the next

positioning when the machine code is ON. M

codes are turned OFF by the PLC program.

Code Nos. from 1 to 65535 assigned by the

user and used (1: Clamp, 2: Loosen, etc.).

Comments can be written after 50 of the M

codes, and they can be monitored using a

peripheral device or displayed on an external

display. Refer to "AFTER MODE" and "WITH

MODE".

MACHINE FEED VALUE

The OP address at the completion of the

machine OPR is stored.

The current position of the machine

coordinates determined by a machine having

the OP address as a reference.

Even if the current value is changed, this value

will not change.

MANUAL PULSE GENERATOR

The handle of this device is manually rotated

to generate pulses. This device is used when

manually carrying out accurate positioning.

Made by Mitsubishi Electric Corp.

(model: MR-HDP01)

MASTER AXIS

When carrying out interpolation operations,

this is the side on which the positioning data is

executed in priority. For example, when

positioning with the X axis and Y axis, the side

with the largest movement distance will

become the master axis, and the speed will

follow that axis. The slave axis speed will be

ignored.