1 - 6

MELSEC-Q

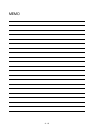

1 PRODUCT OUTLINE

Lifter (Storage of Braun tubes onto aging rack)

PLC MELSEC-Q

Servo amplifier

Servomotor

B conveyor

Unloader

Loader/unloader

Aging rack

Lifter C

conveyor

Counter-

weight

A conveyor Servo amplifier

Reduction

gears

Servomotor

(with brakes)

Loader

Positioning module

G2

G1

QD75

•

During the aging process of braun tubes,

storage onto the rack is carried out by

positioning with the AC servo.

•

The up/down positioning of the lifter is carried

out with the 1-axis servo, and the horizontal

position of the aging rack is positioned with the

2-axis servo.

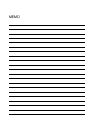

Index table (High-accuracy indexing of angle)

Detector

Servomotor

Worm gears

Index table

Digital switch

PLC

MELSEC-Q

AD75

Servo

amplifier

QD75

•

The index table is positioned at a high accuracy

using the 1-axis servo.

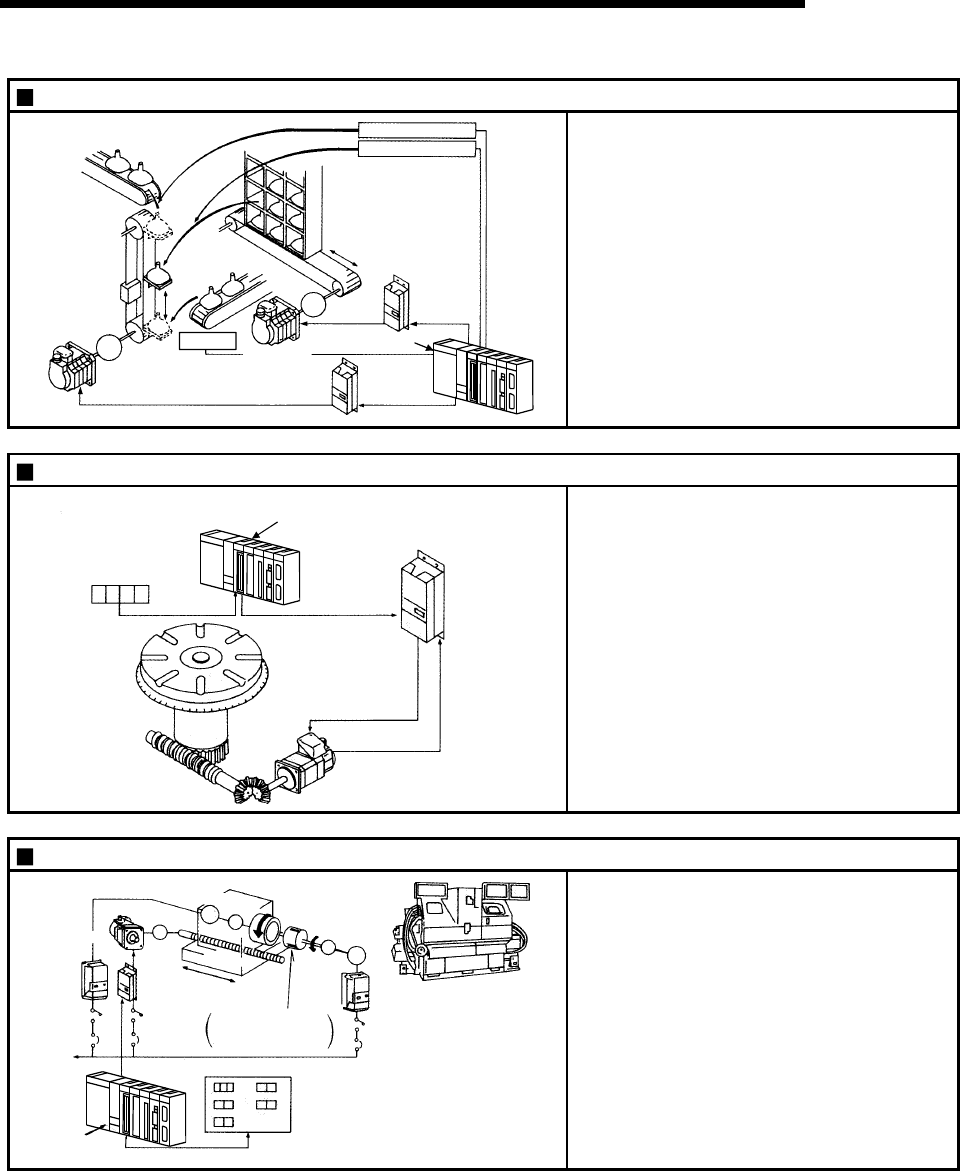

Inner surface grinder

PLC

MELSEC-Q

QD75

a

b

c

d

e

Servomotor

Servo

amplifier

220VAC

60Hz

1M

G

Inverter

Motor

Grinding stone

Workpiece

Motor

Fix the grinding

stone, feed the

workpiece, and grind.

Operation panel

G

1M

a. Total feed

amount (mm)

b. Finishing

feed amount (mm)

c. Compensation

amount (mm)

d. Rough grind-

ing speed (mm/s)

e. Fine grinding

speed (mm/s)

Inverter

•

The grinding of the workpiece's inner surface

is controlled with the servo and inverter.

•

The rotation of the workpiece is controlled with

the 1-axis inverter, and the rotation of the

grinding stone is controlled with the 2-axis

inverter. The workpiece is fed and ground with

the 3-axis servo.