15 - 23

MELSEC-Q

15 TROUBLESHOOTING

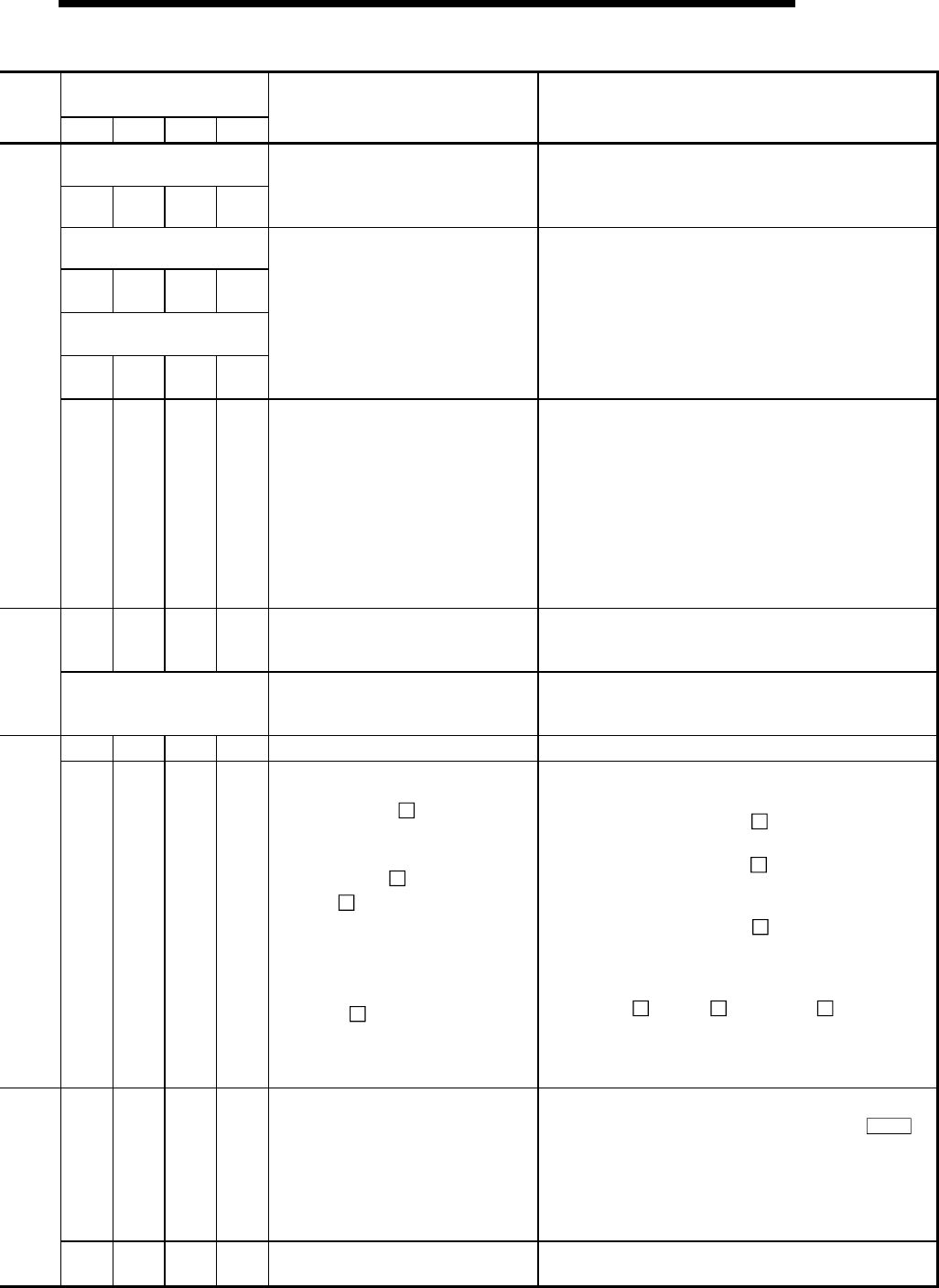

Related buffer memory

address

Axis 1 Axis 2 Axis 3 Axis 4

Set range

(Setting with sequence program)

Remedy

ABS setting direction in the

unit of degree

1550 1650 1750 1850

0: Shortcut

1: Clockwise

2: Counterclockwise

• Set the ABS setting direction in the unit of degree

within the setting range.

• Set "0" when the software stroke limits are valid.

(Refer to Section 9.1.5)

Software stroke limit

upper limit

18

19

168

169

318

319

468

469

Software stroke limit

lower limit

20

21

170

171

320

321

470

471

• [mm] [inch] [pulse]

–2147483648 to 2147483647

• [degree]

0 to 35999999

Invalidate the software stroke limit.

(To invalidate, set the software stroke limit upper limit

value to the software stroke limit lower limit value.)

(Refer to Section 9.1.5)

———— —

Clear the setting of the PLC CPU module parameter

"Output at error stop".

(Refer to "QCPU User’s Manual")

———— —

The flash ROM is expected to be at the end of its

writable life.

Replace the flash ROM with a new one.

1901

<Parameter initialization request>

1: Parameter initialization is

requested

Return the parameter to that set at the time of delivery

from the plant. (Refer to Section 13.2)

— — — — — (Refer to "QCPU User’s Manual")

————

<ABRST status>

0: Communication complete

(received from the servo amplifier)

<PSTRT start No.>

<TEACH teaching data selection>

0: The current feed value is written to

the positioning address.

1: The current feed value is written to

the arc address.

<TEACH positioning data No.>

1 to 600

• When executing the ABRST

instruction, set the

status to 0 (refer to Section 14.3).

• When executing the PSTRT instruction, set the

start No. to within the setting range (refer to Section

14.4).

• When executing the TEACH

instruction, set the

teaching data selection and positioning data No. to

within the setting range (refer to Section 14.5).

• Do not specify the instruction of a non-existent axis by

the ABRST

, PSTRT and TEACH instructions

(refer to Section 14.3 to Section 14.5).

———— —

Review the sequence program so that data is not

written continuously to the flash ROM. (Using

Md.19

in

Section 5.6.1, the number of flash ROM write times can

be monitored.)

(If this error has occurred in a proper using method,

writing is enabled by resetting the error, switching

power OFF, then ON, or resetting the PLC CPU.)

— — — — — A trouble occurs. Repair.