1 - 5

MELSEC-Q

1 PRODUCT OUTLINE

1.1.2 Purpose and applications of positioning control

"Positioning" refers to moving a moving body, such as a workpiece or tool (hereinafter,

generically called "workpiece") at a designated speed, and accurately stopping it at the

target position. The main application examples are shown below.

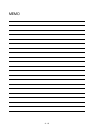

Punch press (X, Y feed positioning

)

Y axis

servomotor

Gear and ball screw

Y axis

X axis

Y axis

320mm

160mm

15m/min

(2000r/min

)

15m/min

(1875r/min)

12 s

AD75

Press head

Servo

a

mplifier

X axis

Gear and rack & pinion

X axis

servomotor

PLC

MELSEC-Q

X axis

Y axis

Servo

amplifier

Press

punching

QD75

•

To punch insulation material or leather, etc.,

as the same shape at a high yield, positioning

is carried out with the X axis and Y axis

servos.

•

After positioning the table with the X axis

servo, the press head is positioned with the Y

axis servo, and is then punched with the

press.

•

When the material type or shape changes, the

press head die is changed, and the positioning

pattern is changed.

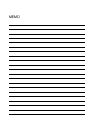

Palletizer

Servo amplifier

PLC

MELSEC-Q

AD75

Conveyor control

Conveyor

Servomotor

(with brakes)

Position detector

Reduction

gears

Ball screw

(From QD75)

Palletizer

Unloader control

Teaching unit

AD75TU

G

QD75

•

Using the servo for one axis, the palletizer is

positioned at a high accuracy.

•

The amount to lower the palletizer according to

the material thickness is saved.

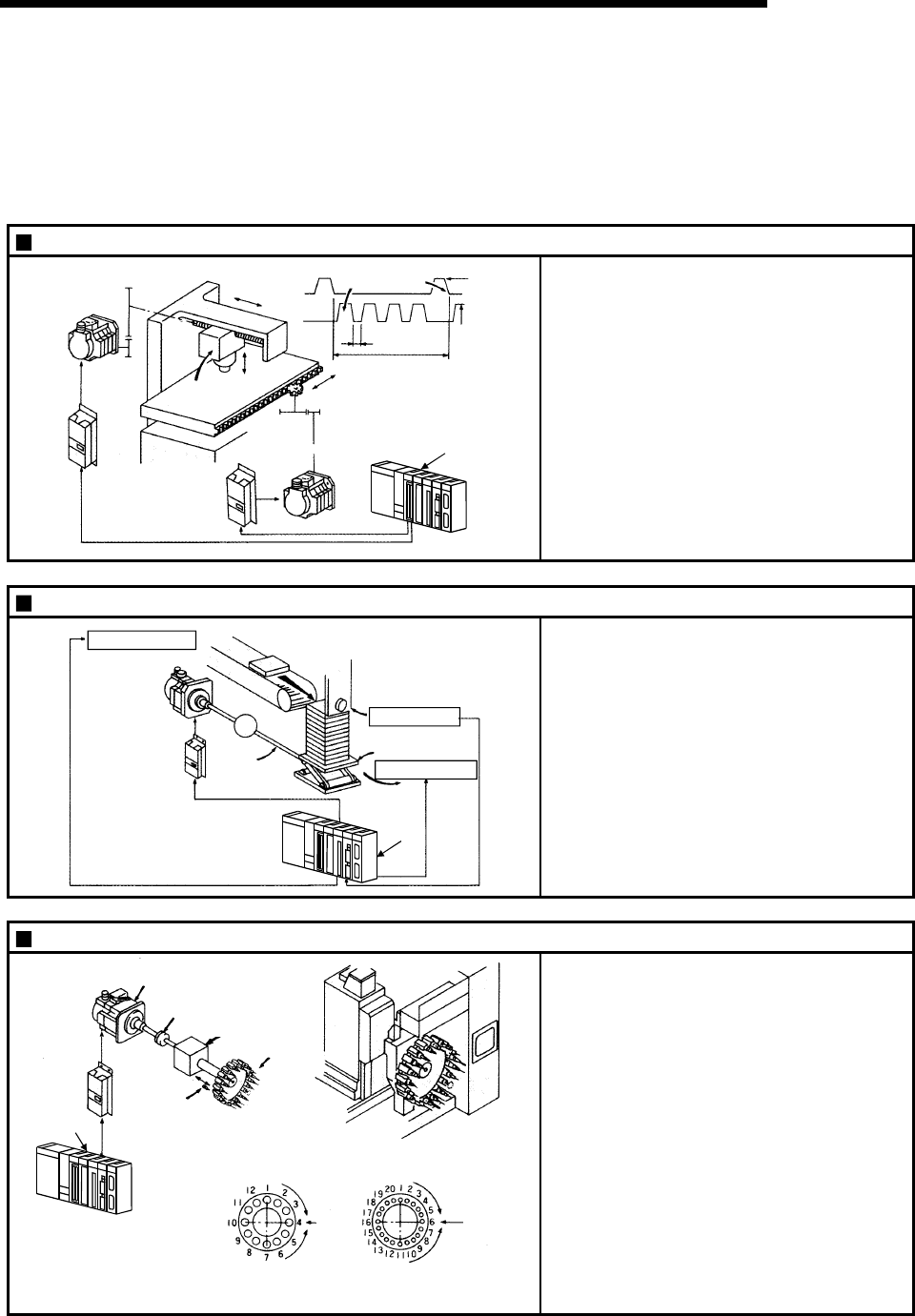

Compact machining center (ATC magazine positioning)

Servomotor

Servo

amplifier

PLC

MELSEC-Q

AD75

Coupling

ATC tool

magazine

Reduction

gears

Positioning

pin

Tool

(12 pcs., 20 pcs.)

<No. of tools: 12> <No. of tools: 20>

Current

value

retrieval

position

Current

value

retrieval

position

Rotation direction

for calling

11, 12, 1, 2 or 3

Rotation direction

for calling

17 to 20, 1 to 5

Rotation direction

for calling 5, 6, 7, 8, 9 or 10

Rotation direction

for calling 7 to 16

QD75

•

The ATC tool magazine for a compact

machining center is positioned.

•

The relation of the magazine's current value

and target value is calculated, and positioning

is carried out with forward run or reverse run to

achieve the shortest access time.