12 - 71

MELSEC-Q

12 CONTROL SUB FUNCTIONS

[2] Precautions during control

(1) Before teaching, a "machine OPR" must be carried out to establish the OP.

(When a current value changing, etc., is carried out, "

Md.20

Current feed

value" may not show absolute addresses having the OP as a reference.)

(2) Teaching cannot be carried out for positions to which movement cannot be

executed by manual control (positions to which the workpiece cannot

physically move). (During center point designation circular interpolation

control, etc., teaching of "

Da.7

Arc address" cannot be carried out if the

center point of the arc is not within the moveable range of the workpiece.)

(3) Writing to the flash ROM can be executed up to 100,000 times.

If writing to the flash ROM exceeds 100,000 times, the writing may become

impossible (assured value is up to 100,000 times).

If an error (error code: 805) occurs when writing to the flash ROM has been

completed, check whether or not the program is created so as to write

continuously to the flash ROM.

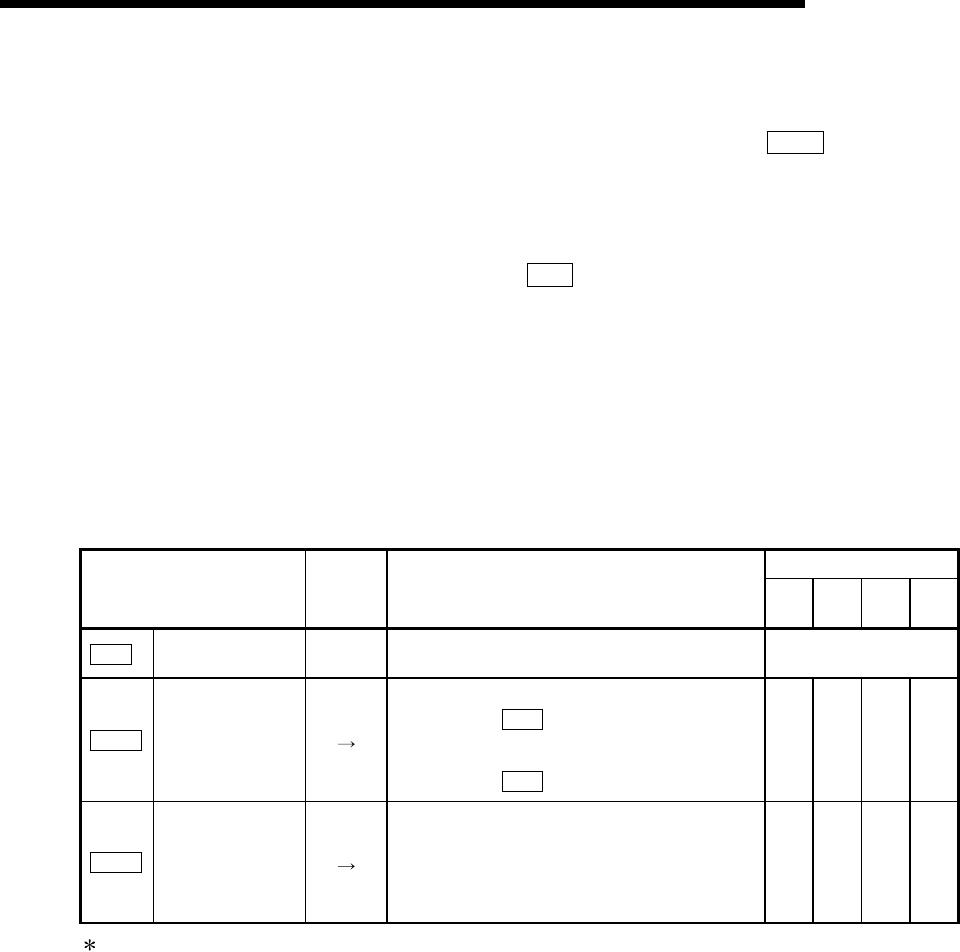

[3] Data used in teaching

The following control data is used in teaching.

Buffer memory address

Setting item

Setting

value

Setting details

Axis

1

Axis

2

Axis

3

Axis

4

Cd.1

Flash ROM write

request

1

Write the set details to the flash ROM (backup

the changed data).

1900

Cd.38

Teaching data

selection

Sets to which "current feed value" is written.

0: Written to "

Da.6

Positioning

address/movement amount".

1: Written to "

Da.7

Arc address".

1548 1648 1748 1848

Cd.39

Teaching

positioning data

No.

Designates the data to be taught.

(Teaching is carried out when the setting value

is 1 to 600.)

When teaching has been completed, the QD75

is zero cleared in the initial stage.

1549 1649 1749 1849

Refer to Section 5.7 "List of control data" for details on the setting details.