2 - 50

2 SYSTEM CONFIGURATION

No.

Name Application

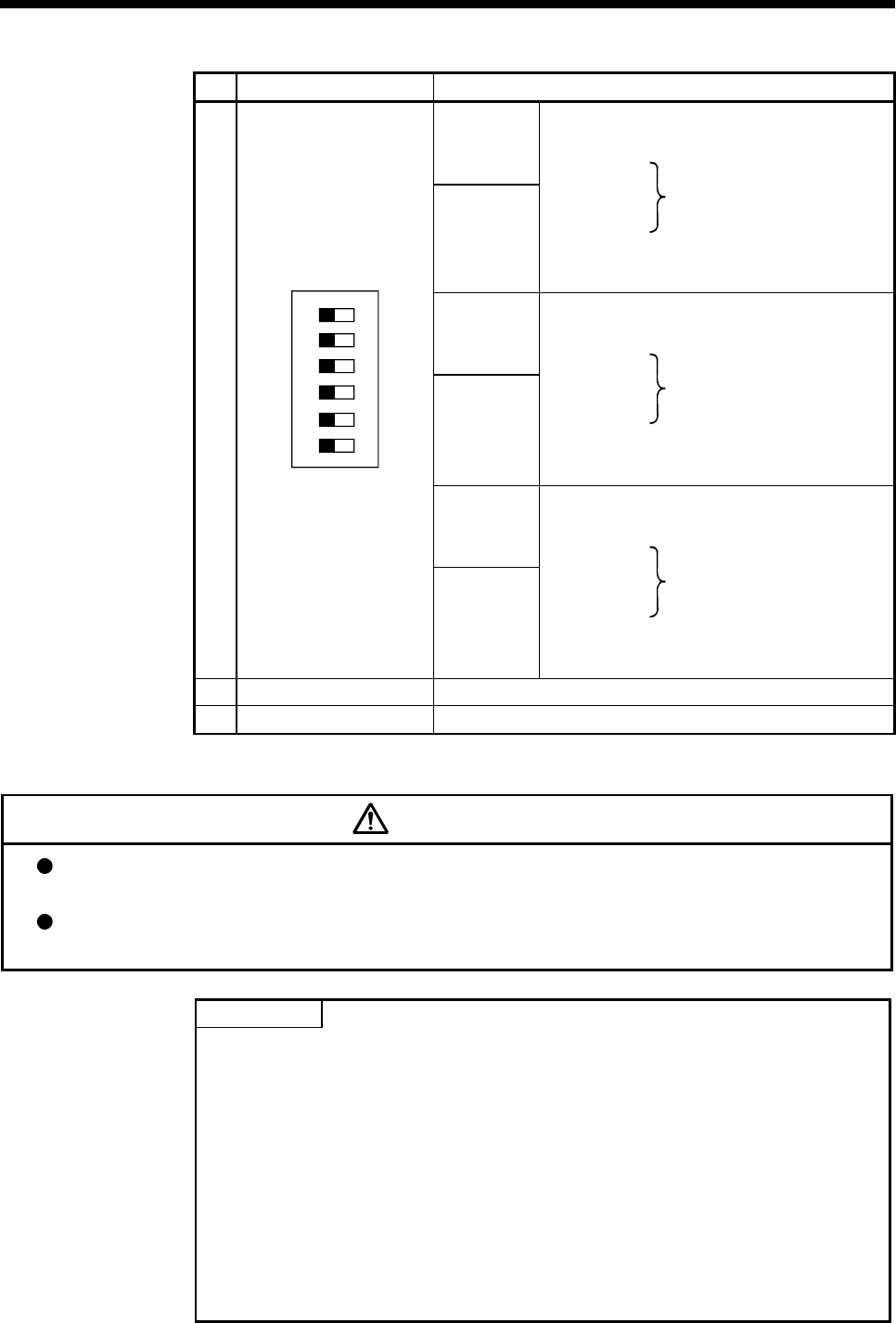

Detection setting of TREN1 signal

SW1 SW2

Dip switch 1

OFF OFF

ON ON

ON OFF

TREN is detected at leading

edge of TREN signal.

Dip switch 2

OFF ON

TREN is detected at trailing edge

of TREN signal.

Detection setting of TREN2 signal

SW3 SW4

Dip switch 3

OFF OFF

ON ON

ON OFF

TREN is detected at leading

edge of TREN signal.

Dip switch 4

OFF ON

TREN is detected at trailing edge

of TREN signal.

Detection setting of TREN3 signal

SW5 SW6

Dip switch 5

OFF OFF

ON ON

ON OFF

TREN is detected at leading

edge of TREN signal.

6)

Dip switches

(Note-1)

123456

ON

(Factory default in OFF

position)

Dip switch 6

OFF ON

TREN is detected at trailing edge

of TREN signal.

7) Module fixing projection Projection used to fix to the base unit.

8) Serial number display Display the serial number described on the rating plate.

(Note-1) : The function is different according to the operating system software installed.

CAUTION

Before touching the DIP switches, always touch grounded metal, etc. to discharge static

electricity from human body. Failure to do so may cause the module to fail or malfunction.

Do not directly touch the module's conductive parts and electronic components. Touching them

could cause an operation failure or give damage to the module.

POINTS

Input indicator LED of the manual pulse generator/incremental synchronous

encoder phases A, B and tracking enable signal turns ON at the following

conditions.

(1) PLS.A 1 to 3, PLS.B 1 to 3

• Q173DPX is set in the system setting of MT Developer2.

• All axes servo ON command (M2042) turned on.

• Manual pulse generator enable flag (M2051, M2052, M2053) turned on.

• Manual pulse generator signal is input.

(2) TREN 1 to 3

• Q173DPX is set in the system setting of MT Developer2.

• The tracking enable signal is input.