5 - 4

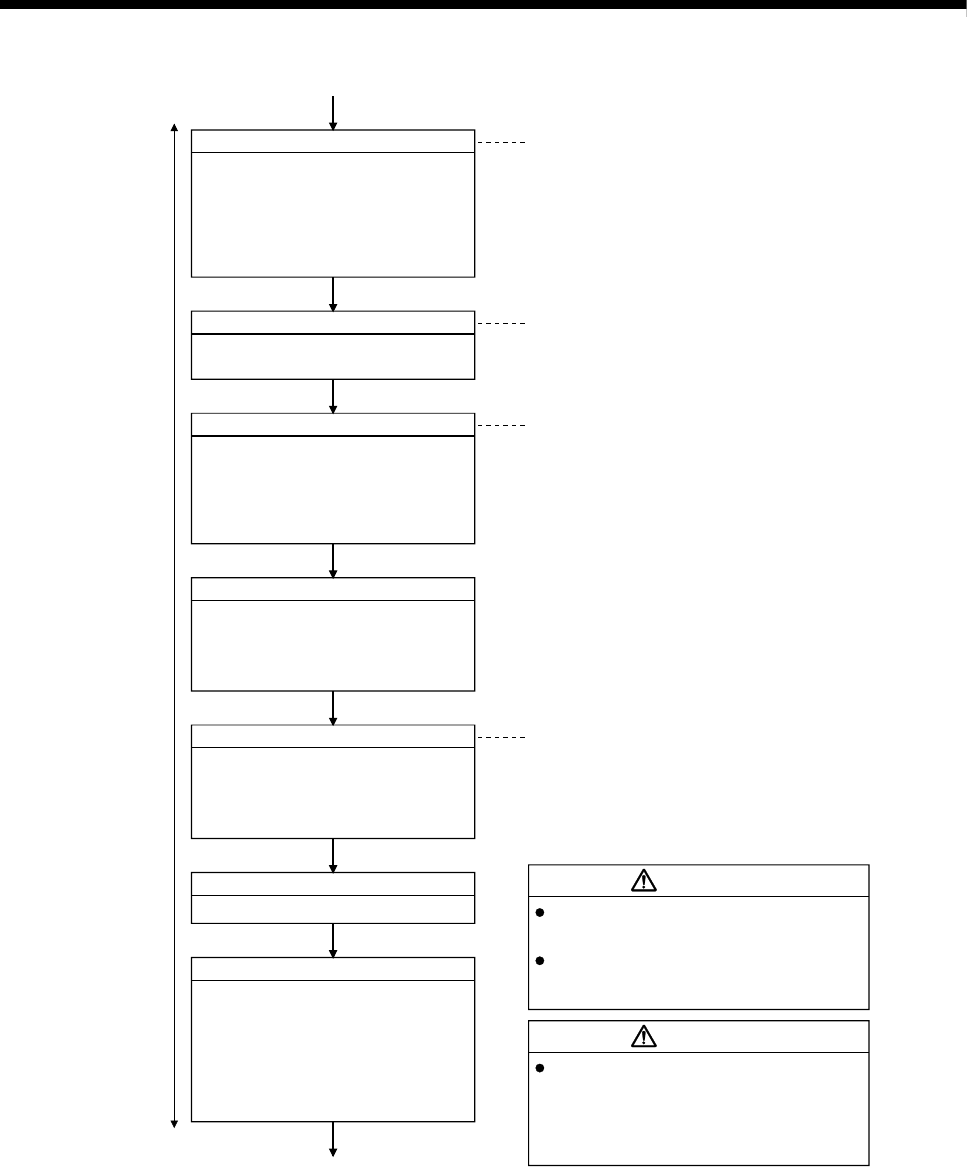

5 START-UP PROCEDURES

1)

Refer to Section 2.5.3

Check external inputs to Q172DLX

Check the wiring of following external inputs

by monitoring of MT Developer2.

(1) FLS (Upper stroke limit input)

(2) RLS (Lower stroke limit input)

(3) STOP (Stop signal)

(4) DOG (Proximity dog)

Motion CPU

area

Set parameter values to those that are compatible

with the Motion controller, servo amplifier,

servo motor and regenerative resistor model name

and the system name application.

The protective functions may not function if the

settings are incorrect.

Do not mount a phase advancing capacitor, surge

absorber or radio noise filter (option FR-BIF) on

the output side of the servo amplifier.

Correctly connect the output side (terminal U, V,

W). Incorrect connections will lead the servo motor

to operate abnormally.

Check the wiring of following external inputs

by monitoring of MT Developer2 or LED

indicators.

(1) Manual pulse generator/incremental

synchronous encoder setting

Refer to Section 2.5.4

Check external inputs to Q173DPX

Check I/O module

Check the wiring of I/O modules.

CAUTION

CAUTION

Set the following positioning parameters

using MT Developer2.

(1) Fixed parameters

(2) Home position return data

(3) JOG operation data

(4) Servo parameters

(5) Parameter block

(6) Limit output data

Positioning parameters setting

[Servo data setting]

2)

Check servo external inputs signal

Check the wiring of servo external input

signals by monitoring of MT Developer2.

(1) FLS (Upper stroke limit input)

(2) RLS (Lower stroke limit input)

(3) DOG (Proximity dog)

Refer to Section 2.5.1

Check pulse input signal of internal I/F

Check the wiring of pulse input signals of

internal I/F by monitoring of MT Developer2.

(1) Check that the current value storage

register (D1120, D1121) counts when

a manual pulse generator or

incremental synchronous encoder is

used.

Check I/O signal of internal I/F

Check the wiring of I/O signals of internal

I/F.

Refer to Section 2.5.1