APP - 33

A

PPENDICES

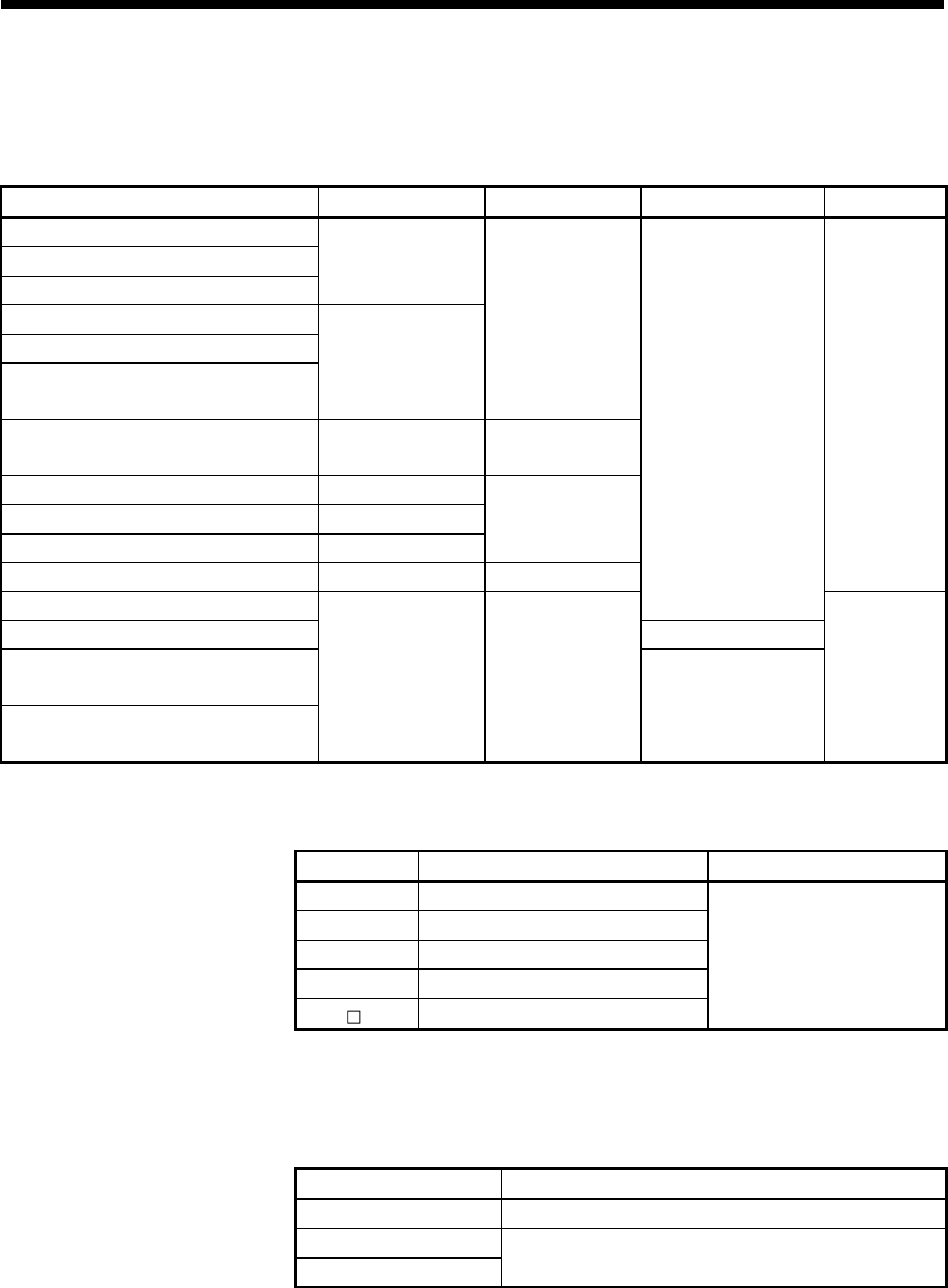

(d) Mark detection data

Set the data to latch at mark detection.

1) Motion control data

Item Unit Data type Axis No. setting range Remarks

Feed current value

Real current value

Motor real current value

10

-1

[µm], 10

-5

[inch],

10

-5

[degree], [PLS]

Servo command value

Position feed back

Absolute position encoder within one-

revolution position

[PLS]

32-bit integer type

Absolute position encoder within multi-

revolution position

— 16-bit integer type

Deviation counter value [PLS]

Servo command speed [PLS/s]

Motor speed 0.01[r/min]

32-bit integer type

Motor current 0.1[%] 16-bit integer type

—

Virtual servomotor feed current value

1 to 16

Synchronous encoder current value 1 to 8

Current value within one cam shaft

revolution

Current value within one cam shaft

revolution (Actual)

(Note)

[PLS] 32-bit integer type

1 to 16

Valid in SV22

virtual mode

only

(Note): Current value within one cam shaft revolution takes into consideration the delay of the servo amplifier.

2) Word device data

Word device Setting range Remarks

D 0 to 8191

W 0 to 1FFF

# 0 to 9215

SD 0 to 1999

U \G

10000 to (10000+p-1)

(Note-1)

—

(Note-1): "p" indicates the user setting area points of the Multiple CPU high speed transmission

area for each CPU.

3) Data type

Set the data at word device data setting.

Data type Remarks

16-bit integer type —

32-bit integer type

64-bit floating-point type

Set the device No. as an even No.