9. Exclusive Commands

- 249 -

9.6.6 Example of chopping control by program command

In the example given below, the upper dead center point (increment from the basic position), bottom

dead center point (increment from the upper dead center point), and number of cycles (times/min) are

set using G code macro.

The above data is set to the local variables by G code macro. The local variable data is read by the

ladder upon execution of M code (M10). Then, chopping is started upon DDB function instruction. The

chopping is stopped by the ladder upon execution of M code (M11).

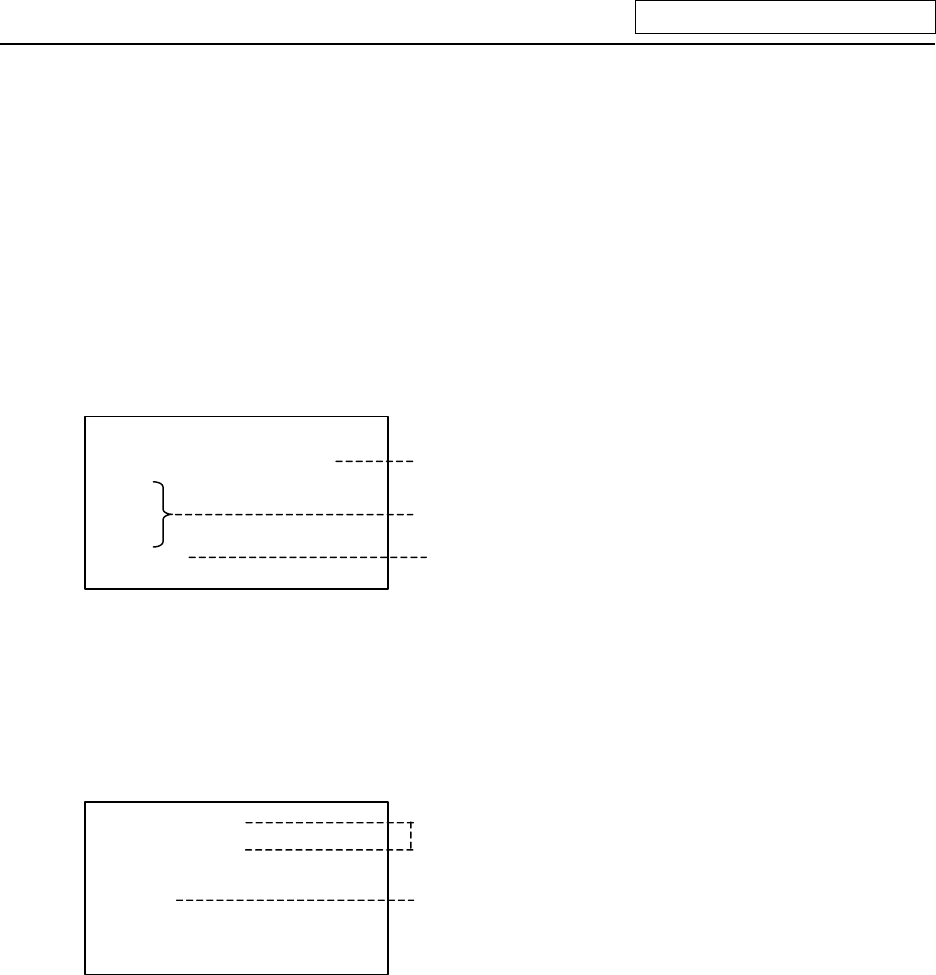

(1) G code macro execution

The following is an example in which O9000 is defined as the sub-program of G200 (G65 macro

type).

:

G200 Z-20. Q-10. R50. ;

:

:

:

M11 ;

#26=#26*1000 ;

#17=#17*1000 ;

G04 ;

M10 ;

M99 ;

A

rgument of G200

Z : Upper dead center point (Increment from the basic position)

Q : Bottom dead center point (Increment from the upper dead center point)

R : Number of cycles/min.

Main program

O9000

Chopping start

Shape

Chopping stop

Value of Z, Q, R: local

variables set to #26, #17, #18

Chopping start

(Note 1) As for Z, Q commands, even if a decimal place is omitted (Ex. Z-20. → Z-20), the unit is

remained mm.

(Note 2) With the submicron system, change the constant for macro operation from 1000-fold to

10000-fold.

(Note 3) When a macro call is executed, the nesting level of local variable will be 1, and the level of

local variable will also be 1. So, the number of layers of nesting has to be kept to 4.