9. Exclusive Commands

- 219 -

(1) Procedure when tool command is executed

(a) Tool life management I

1) When tool command (T command) is given, the controller outputs T code data and start

signal (TF). (Note) The T code data (BCD) is binary converted and then used.

2) The user PLC checks the tool command. If life management is required, the user PLC

executes the spare tool selection command.

3) The spare tool selection command outputs the tool data of the tool corresponding to the

specified tool number.

4) The user PLC decides whether or not the tool can be used according to the status in the

output tool data, and selects command tool or performs alarm processing.

(Note) If -1 is set in the group number in the output tool data, the tool data is invalid. At

the time, the specified tool number is output to the tool number in the output tool

data as it is.

(b) Tool life management II

1) When tool command (T command) is given, the controller outputs T code data and start

signal (TF). (Note) The T code data (BCD) is binary converted and then used.

2) The user PLC checks the tool command. If life management is required, the user PLC

executes the spare tool selection command.

3) The spare tool selection command selects the spare tool corresponding to the specified

number (group number, tool number) and outputs the tool data of the spare tool.

4) The user PLC decides whether or not the tool can be used according to the status in the

output tool data, and selects command tool or performs alarm processing.

(Note) If -1 is set in the group number in the output tool data, the tool data is invalid. At

the time, the specified tool number is output to the tool number in the output tool

data as it is.

(2) Procedure when spindle tool is changed

1) When spindle tool is changed during the spindle tool change command (M06), etc., the user

PLC specifies the tool number of the spindle tool (R3720~R3721).

The controller outputs the spindle tool data corresponding to the tool number of the spindle

tool every user PLC main cycle (R3724~R3735).

2) The controller integrates the use time or use count of the spindle tool based on the spindle

tool data in the tool data file.

In tool life management II, it also executes tool offset corresponding to the spindle tool.

(Note) If -1 is set in the group number in the output spindle tool data, the spindle tool data is

invalid. At the time, the specified tool number (R3720~R3721) is output to the tool

number in the output spindle tool data as it is. The controller does not integrate the

usage time or usage count of the spindle tool or make tool offset.

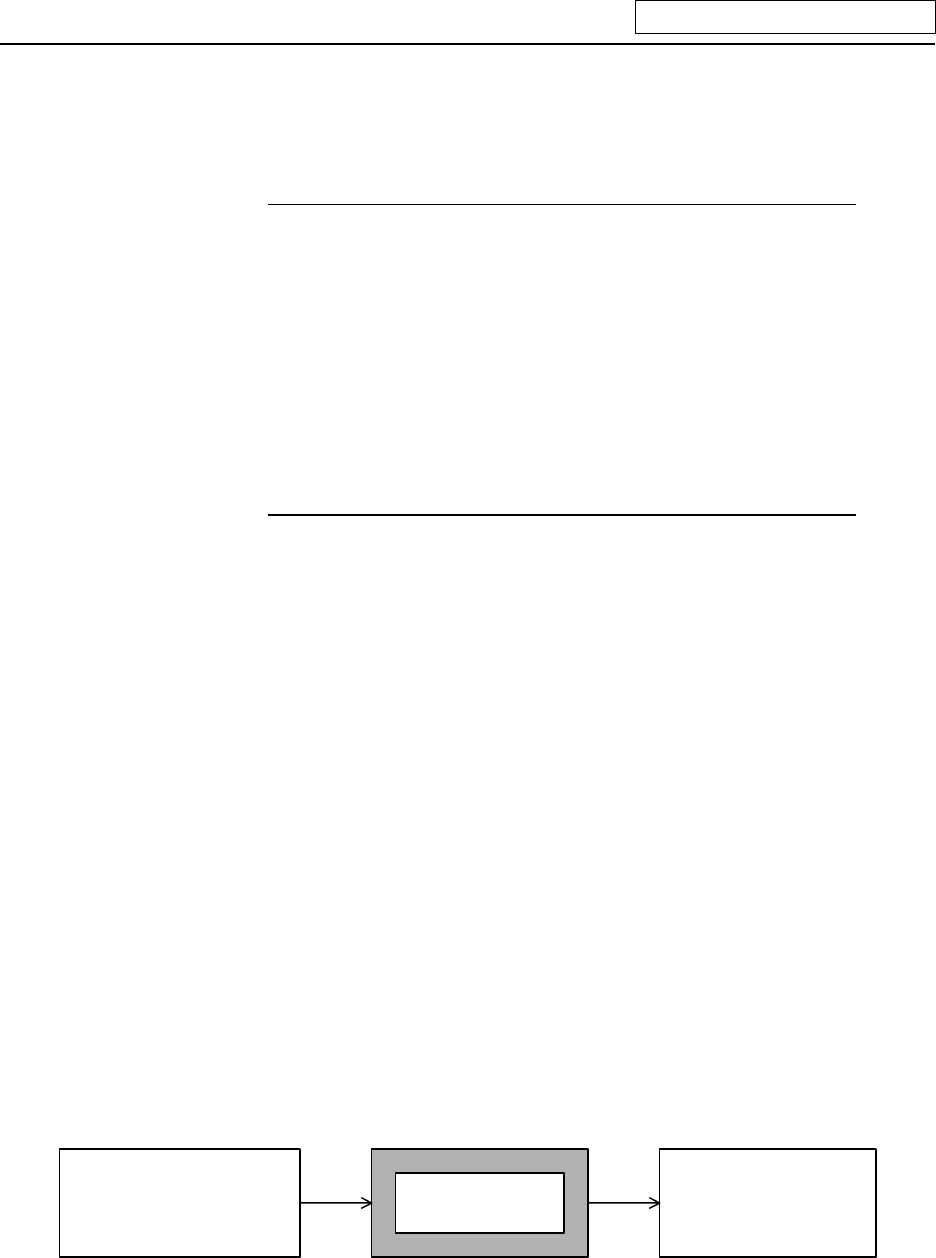

<When tool command is executed>

In tool life management I,

tool number is only specified

and spare tool is selected.

Tool data (Rn)

Tool command (Rm)

(Tool number, group number)

Spare tool selection

function command

Tool is selected according

to tool number in tool data.

(User PLC)