9. Exclusive Commands

- 224 -

1) Spare tool compensation system

Tool compensation corresponding to the spindle tool can be made in tool life

management II.

One of the following three types of length and compensation can be selected by setting

tool data:

i) Compensation umber system (0 is set on the tool data registration screen.)

Compensation data in tool data is handled as the compensation number. It is

replaced with the compensation number given in a work program and compensation

is executed.

ii) Addition compensation system (1 is set on the tool data registration screen.)

Compensation data in tool data is handled as addition offset amount. It is added to the

offset amount indicated by the compensation number given in a work program and

compensation is executed.

iii) Direct compensation system (2 is set on the tool data registration screen.)

Compensation data in tool data is handled as direct offset amount. It is replaced with

the offset amount indicated by the compensation number given in a work program

and compensation is executed.

2) Usage data count system

i) Usage time count

For usage data, the execution time of cutting feed (such as G01, G02, or G03) is

counted in 3.75-s

units. However, the life data and usage data are displayed in minute

units on the tool data registration screen.

ii) Number of times tool has been mounted is counted

When tool is used as spindle tool in tool change, etc., usage data is counted. However,

if cutting feed (G01, G02, or G03) is not executed after tool is used as spindle tool,

usage data is not counted.

iii) Number of cutting times is counted

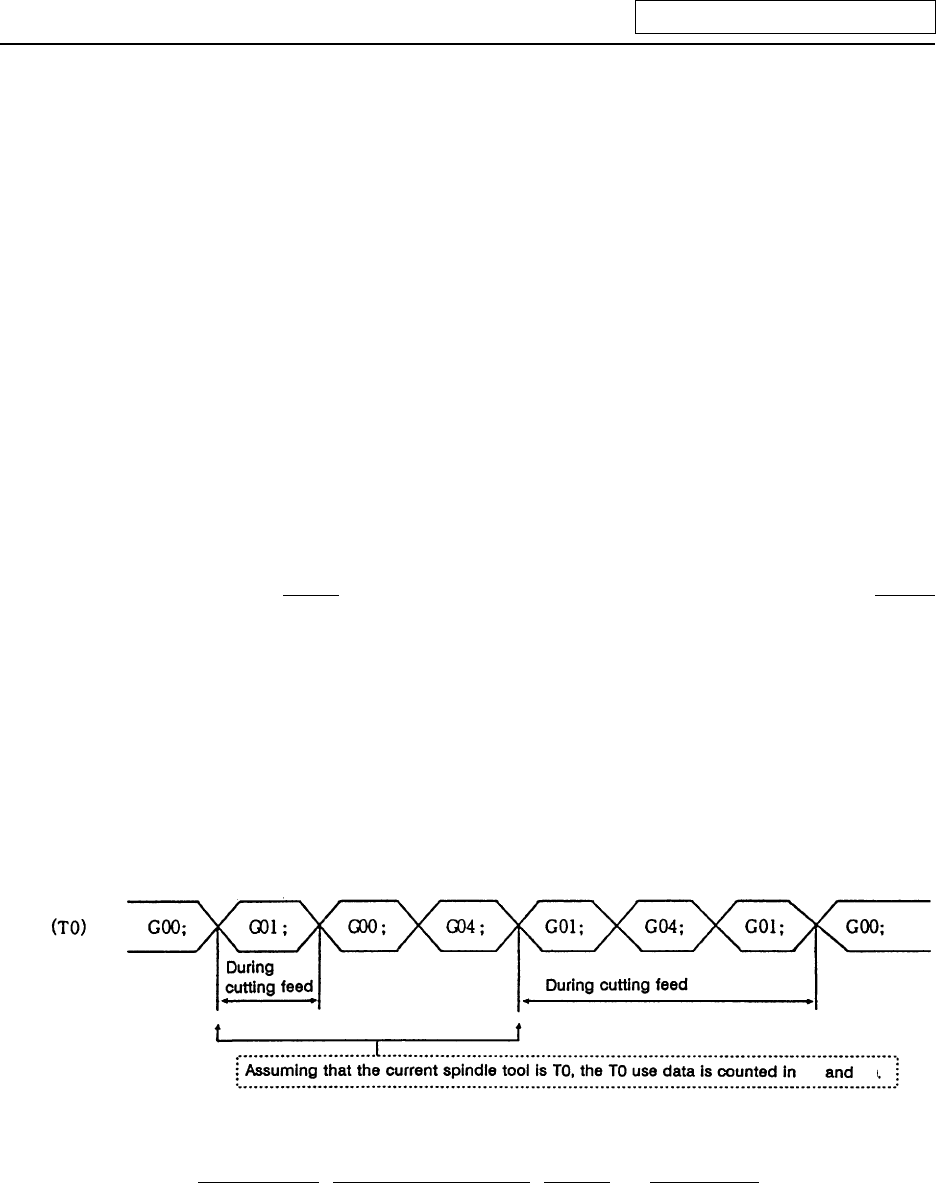

Usage data is counted when a change is made from rapid traverse feed (such as

G00) command to cutting feed (such as G01, G02, or G03) command as shown

below. However rapid traverse or cutting feed command with no movement becomes

invalid.

Even if a command other than the rapid traverse command appears between cutting

feed commands, usage data is not counted.

A

B

A B

Caution:

When none of the tool life management input signal and use data count validity signal are input

or during machine lock

, auxiliary function lock, dry run, or single block, usage data is not

counted.

· The usage data is not counted when the life data is 0.

· Life management is executed even in the MDI operation mode.

· The usage data is not counted even when the status is 2 or more (normal life, error tool 1,

error tool 2).