EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

74-2958—132

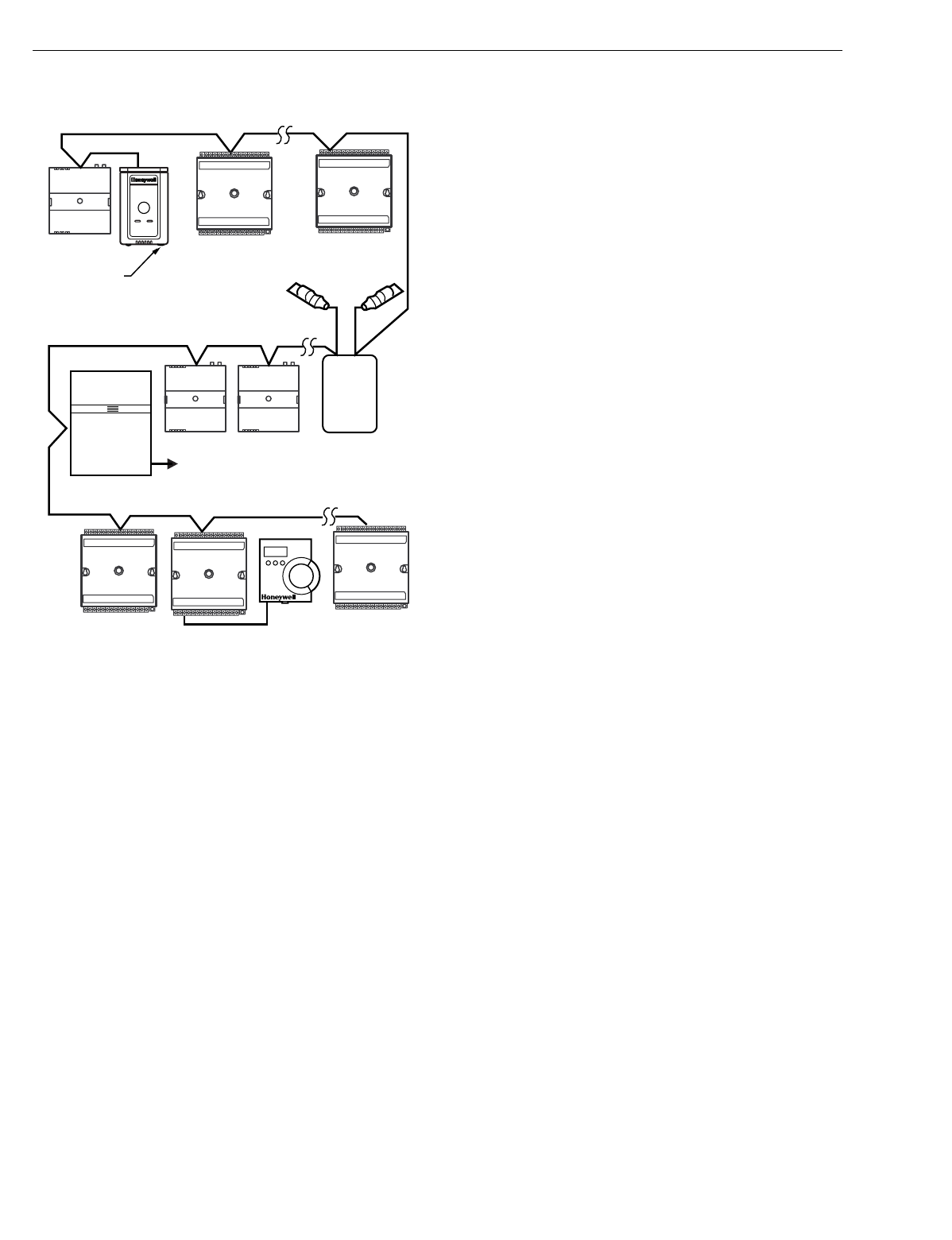

Fig. 20. Wiring layout for two singly terminated

L

ON

W

ORKS

®

Bus segments.

NOTE: See the L

ON

W

ORKS

Bus Termination Module section

for wirin

g

details.

IMPORTANT

Notes on communications wiring:

• All field wiring must conform to local codes and ordi-

nances or as specified on installation wiring dia-

grams.

• Approved cable types for L

ON

W

ORKS

Bus communi-

cations wiring is Level IV 22 AWG (0.34 mm

2

) ple-

num or non-plenum rated unshielded, twisted pair,

solid conductor wire. For nonplenum areas, use

Level IV 22 AWG (0.34 mm

2

), such as U.S. part

AK3781 (one pair) or U.S. part AK3782 (two pair). In

plenum areas, use plenum-rated Level IV, 22 AWG

(0.34 mm

2

) such as U.S. part AK3791 (one pair) or

U.S. part AK3792 (two pair). See Tables 9 and 11 for

part numbers. Contact Echelon Corp. Technical Sup-

port for the recommended vendors of Echelon

approved cables.

• Unswitched 24 Vac power wiring can be run in the

same conduit as the L

ON

W

ORKS

Bus cable.

• Do not use different wire types or gauges on the

same L

ON

W

ORKS

Bus segment. The step change in

line impedance characteristics causes unpredictable

reflections on the bus. When using different types is

unavoidable, use a Q7751A,B Router at the junction.

• In noisy (high EMI) environments, avoid wire runs

parallel to noisy power cables, or lines containing

lighting dimmer switches, and keep at least 3 in.

(76 mm) of separation between noisy lines and the

L

ON

W

ORKS

Bus cable.

• Make sure that neither of the L

ON

W

ORKS

Bus wires

is grounded.

Power Wiring

A power bud

g

et must be calculated for each Excel 10 W7750

Controller to determine the re

q

uired transformer size for

proper operation. A power bud

g

et is simpl

y

the summin

g

of

the maximum power draw ratin

g

s

(

in VA

)

of all the devices to

be controlled b

y

an Excel 10 W7750 Controller. This includes

the controller itself, the e

q

uipment actuators

(

ML6161, or

other motors

)

and various contactors and transducers, as

appropriate, for the Excel 10 confi

g

uration.

POWER BUDGET CALCULATION EXAMPLE

The followin

g

is an example power bud

g

et calculation for a

t

y

pical Excel 10 W7750B Controller.

Assume a W7750 unit with a fan, two sta

g

es of D/X coolin

g

,

modulatin

g

steam valve for heatin

g

, and modulatin

g

economizer dampers. The power re

q

uirements are:

DeviceVA Information Obtained from

Excel 10 W7750B,C 12.0 W7750 Specification Data

Controller

ML6161 2.2 TRADELINE

Damper Actuator Catalo

g

R8242A 21.0 TRADELINE

Contactor for fan Catalo

g

in-rush ratin

g

D/X Sta

g

es 0.0

NOTE: For this example, assume the coolin

g

sta

g

e outputs

are wired into a compressor control circuit and,

therefore, have no impact on the power bud

g

et.

)

M6410A Steam 0.7 TRADELINE

Heatin

g

Coil Valve Catalo

g

, 0.32A at 24 Vac

TOTAL: 35.9 VA

The Excel 10 S

y

stem example re

q

uires 35.9 VA of peak

power; therefore, a 40 VA AT72D Transformer is able to

provide ample power for this controller and its accessories.

Alternativel

y

, a 75 VA AT88A Transformer could be used to

power two Excel 10 S

y

stems of this t

y

pe, or a 100 VA AT92A

Transformer could be used to power two of these Excel 10

S

y

stems and meet NEC Class 2 restrictions

(

no

g

reater than

100 VA

)

. See Fi

g

. 22 and 23 for illustrations of power wirin

g

details. See Table 8 for VA ratin

g

s of various devices.

EXCEL 10

VAV

EXCEL 10

VAV

EXCEL 10

VAV

EXCEL 10

Q7750A

ZONE

MANAGER

TO C-BUS

(SEE FIG. 1)

L

ONWORKS BUS

SEGMENT NUMBER 2

L

ONWORKS BUS

SEGMENT NUMBER 1

L

ONWORKS BUS

SEGMENT NUMBER 2

T7770

L

ONWORKS

BUS

ACCESS

Q7751A

FTT

L

ONWORKS

BUS

ROUTER

209541B

TERMINATION

MODULE

209541B

TERMINATION

MODULE

M17497

EXCEL 10

CVAHU

EXCEL 10

CVAHU

EXCEL 10

CVAHU

EXCEL 10

CVAHU

EXCEL 10

CVAHU

T7560A,B