EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

74-2958—124

Allowable Heating and Cooling Equipment

Configurations

Each W7750 device can control a variet

y

of different t

y

pes of

mechanical coolin

g

and heatin

g

e

q

uipment within roof top air

handlers. See Fi

g

. 13 throu

g

h 17 for a conceptual overview of

some t

y

pical confi

g

urations. For specific wirin

g

details, see

the Prepare Wirin

g

Dia

g

rams section.

STAGED HEATING/COOLING CONTROL

Sta

g

ed e

q

uipment control is available for up to four sta

g

es of

heatin

g

or four sta

g

es of coolin

g

. On the W7750, the sta

g

es

are activated throu

g

h di

g

ital outputs

(

Triacs on the W7750B,C

and dr

y

-contact rela

y

s on the W7750A

)

one for each sta

g

e

wired to 24 Vac contactors

(

see Fi

g

. 27 and 30 in Step 4.

Prepare Wirin

g

Dia

g

rams section for wirin

g

details

)

. Note that

the number of ph

y

sical Di

g

ital Outputs

(

DOs

)

on the controller

limits the total number of sta

g

es that can be controlled. For

example, the W7750A Model has six di

g

ital outputs, and

because one is used for the suppl

y

fan, there are five DOs

available for an

y

combination of heatin

g

and coolin

g

sta

g

es

(

with a maximum of four sta

g

es of heatin

g

and four sta

g

es for

coolin

g)

. The W7750B Model offers two additional DOs, for a

total of ei

g

ht. The W7750C offers five DOs and three Analo

g

Outputs

(

AOs

)

. Fi

g

. 13 shows a t

y

pical application of two

sta

g

es of heat and two sta

g

es of coolin

g

.

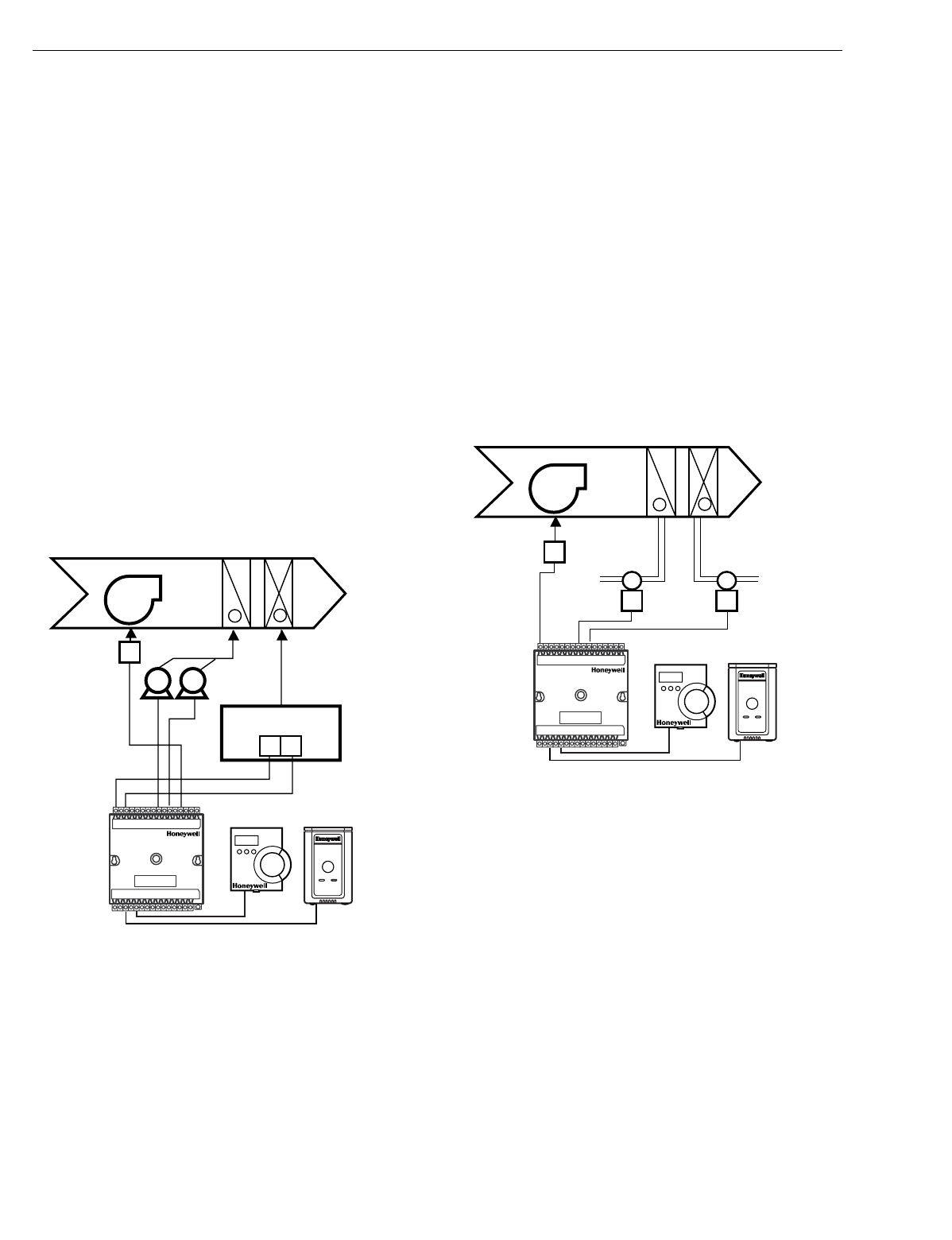

Fig. 13. Fan with two stages of heating and two stages

of cooling.

MODULATING HEATING/COOLING CONTROL

The W7750 Controller provides modulatin

g

e

q

uipment control

for heatin

g

and coolin

g

e

q

uipment

(

and economizer dampers,

see Fi

g

. 16

)

usin

g

either Series 60 Floatin

g

Control or Pulse

Width Modulated

(

PWM

)

control,

(

PWM control is available on

the W7750B,C

only

)

. The Series 60 Modulatin

g

Control is

provided throu

g

h two Rela

y

di

g

ital outputs on the W7750A or

two Triac di

g

ital outputs on the W7750B,C

(

one to pulse the

valve actuator open and one to pulse it closed

)

. PWM control

positions the actuator based on the len

g

th, in seconds, of the

pulse from the di

g

ital output. For PWM, the controller outputs

a pulse whose len

g

th consists of two parts, a minimum and a

maximum. The minimum pulse time represents the analo

g

value of 0 percent and the maximum pulse len

g

th that

represents an analo

g

value of 100 percent. If the analo

g

value

is

g

reater than 0 percent, an additional time is added to the

minimum pulse time. The len

g

th of time added is directl

y

proportional to the ma

g

nitude of the analo

g

value. The PWM

actuator will be

g

in to use the analo

g

value at the end of the

pulse and will continue to use this value until a new pulse is

received. Refer to Appendix B under PWM Control for an

example. Series 60 actuators are

g

enerall

y

less expensive

than those for PWM, but the trade-off is that PWM re

q

uires

onl

y

a sin

g

le controller di

g

ital output while floatin

g

control

uses two DOs. Refer to Appendix B under Series 60

Modulatin

g

Control for an example. Fi

g

. 14 illustrates a

s

y

stem with modulatin

g

heatin

g

and coolin

g

(

see Fi

g

. 29 and

31 in Step 4. Prepare Wirin

g

Dia

g

rams section.

Fig. 14. Fan, modulating heating and modulating cooling.

NOTE: Pneumaticall

y

actuated valves can be controlled

usin

g

a pneumatic transducer device. See Fi

g

. 17.

Also, transducer devices are available from third

part

y

vendors to convert PWM outputs to a volta

g

e

or current si

g

nal if desired.

HEAT PUMP CONTROL

The W7750 Controller handles heat pump applications

similarl

y

to sta

g

ed heatin

g

/coolin

g

control. Heat pump

applications are supported b

y

providin

g

outputs for up to four

compressor sta

g

es, a chan

g

e-over rela

y

for the refri

g

erant

reversin

g

valve, and up to four sta

g

es of auxiliar

y

heat. Note

that the W7750A Model has six di

g

ital outputs, and therefore,

with one DO used for the suppl

y

fan and one for the chan

g

e-

over rela

y

, there are four outputs available for an

y

combination of compressors and auxiliar

y

heat sta

g

es. The

W7750B Model offers two additional DOs for a total of ei

g

ht,

while the W7750C Model offers five DOs and 3 AOs. Fi

g

. 15

illustrates a t

y

pical heat pump s

y

stem with auxiliar

y

heat.

M17491

MIXED

AIR

HEAT

COIL

COOL

COIL

DISCHARGE

AIR

W1

W2

Y1 Y2

-

+

FAN

FAN

STARTER

COMPRESSORS

GAS COMBUSTION

CONTROLS

EXCEL 10

CVAHU

W7750A,B,C

T7560A,B OR T7770

MIXED

AIR

HEAT

COIL

COOL

COIL

DISCHARGE

AIR

-

+

FAN

FAN

STARTER

CHILLED

WATER

VALVE

HOT

WATER

VALVE

M17492

EXCEL 10

CVAHU

W7750A,B,C

T7560A,B OR T7770