EXCEL 10 W7750A,B,C CONSTANT VOLUME AHU CONTROLLER

29 74-2958—1

APPLICATION STEPS

Overview

The seven application steps shown in Table 6 are plannin

g

considerations for en

g

ineerin

g

an Excel 10 W7750 S

y

stem.

These steps are

g

uidelines intended to aid understandin

g

of

the product I/O options, bus arran

g

ement choices,

confi

g

uration options and the Excel 10 W7750 Controller role

in the overall EXCEL 5000

OPEN

SYSTEM architecture.

Table 6. Application Steps.

Step 1. Plan the System

Plan the use of the W7750 Controllers accordin

g

to the

j

ob

re

q

uirements. Determine the location, functionalit

y

and sensor

or actuator usa

g

e. Verif

y

the sales estimate of the number of

W7750 Controllers, T7770 and T7560 Wall Modules re

q

uired

for each model t

y

pe. Also check the number and t

y

pe of

output actuators and other re

q

uired accessories.

When plannin

g

the s

y

stem la

y

out, consider potential

expansion possibilities to allow for future

g

rowth. Plannin

g

is

ver

y

important to be prepared for addin

g

HVAC s

y

stems and

controllers in future pro

j

ects.

T7560 Wall Modules can onl

y

be hard-wired, the

y

have no

L

ON

W

ORKS

Bus access. T7770 Wall Modules can be installed

as either hard-wired I/O-onl

y

devices or additional wirin

g

can

be run to them

(

for the L

ON

W

ORKS

Bus network

)

to allow a

CARE/E-Vision operator terminal to have access to the

L

ON

W

ORKS

Bus. The application en

g

ineer needs to determine

how man

y

wall modules, T7770s and T7560s are re

q

uired. All

T7770 Wall Modules, except the T7770A1006 and the

T7770A1014, can be connected via the L

ON

W

ORKS

Bus

j

ack.

Also the application en

g

ineer needs to know how man

y

T7770s without L

ON

W

ORKS

Bus network connections are

bein

g

installed on the

j

ob, and then clearl

y

document which

wall modules

(

if an

y)

have network access. This information is

re

q

uired durin

g

installation to ensure that the proper number

and t

y

pe of wires are pulled to the wall modules, and the

buildin

g

operators are informed about where the

y

can plu

g

in

to the L

ON

W

ORKS

Bus network with a portable operator

terminal

(

see Fi

g

. 18, 19 and 20

)

. Refer to Step 4. Prepare

Wirin

g

Dia

g

rams for details, about the about the wirin

g

differences between the two t

y

pes.

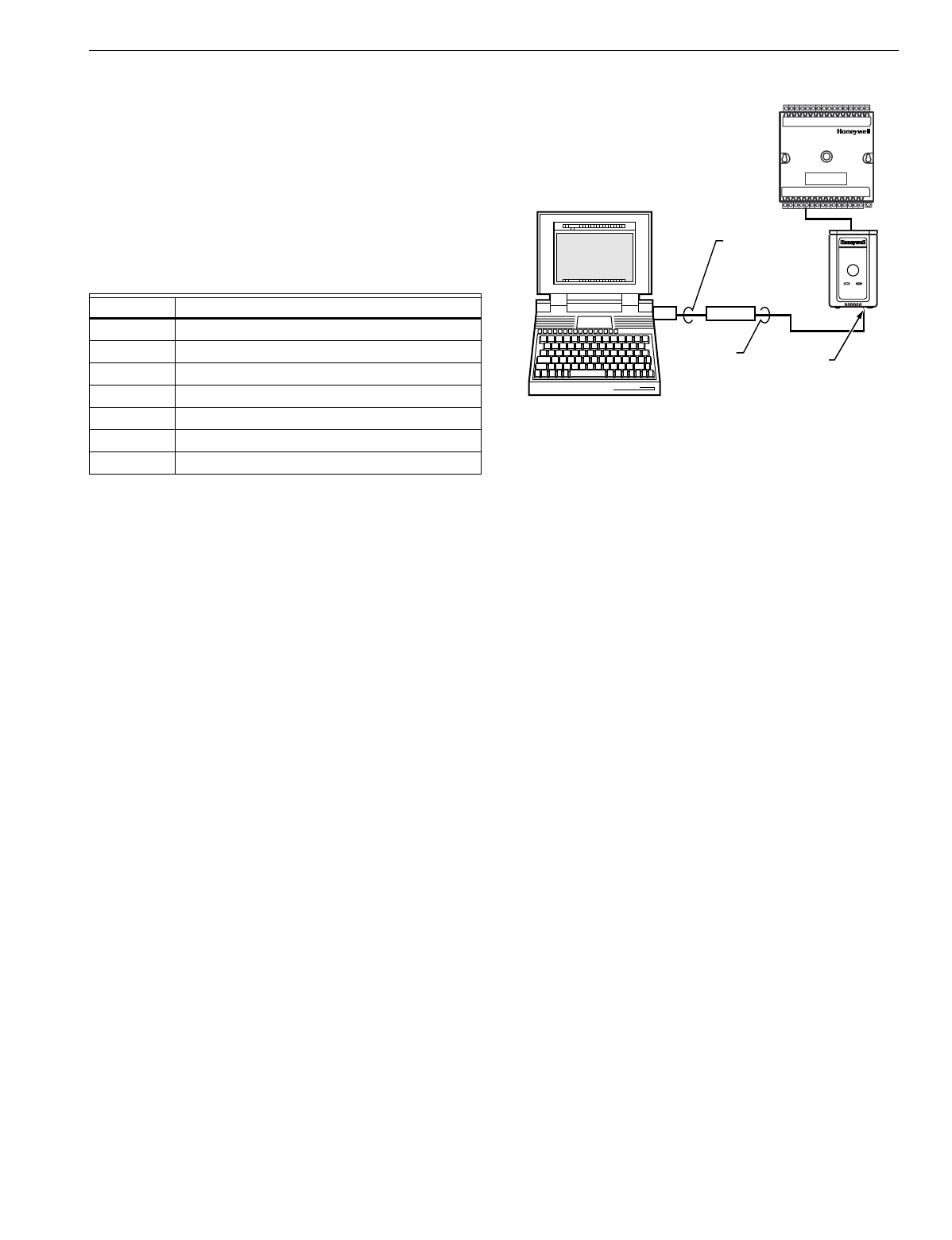

Fig. 18. Connecting the portable operator terminal

to the L

ON

W

ORKS

®

Bus.

The FTT communication wirin

g

,

(

L

ON

W

ORKS

Bus

)

between

controllers is a free topolo

gy

scheme that supports T-tap, star,

loop, and mixed wirin

g

architecture. Refer to the L

ON

W

ORKS

Bus Wirin

g

Guidelines form, 74-2865 for complete description

of network topolo

gy

rules. See Application Step 3. La

y

Out

Communications and Power Wirin

g

, for more information on

bus wirin

g

la

y

out, and see Fi

g

. 27 throu

g

h 35 in Application

Step 4. Prepare Wirin

g

Dia

g

rams, for wirin

g

details.

The application en

g

ineer must review the Direct Di

g

ital

Control

(

DDC

)

j

ob re

q

uirements. This includes the Se

q

uences

of Operation for the W7750 units, and for the s

y

stem as a

whole. Usuall

y

there are variables that must be passed

between the W7750 Controllers and other zone controller

(

s

)

,

or central plant controller

(

s

)

that are re

q

uired for optimum

s

y

stem-wide operation. T

y

pical examples are the TOD Occ/

Unocc si

g

nal, the outdoor air temperature, the demand limit

control si

g

nal, and the smoke control mode si

g

nal.

It is important to understand these interrelationships earl

y

in

the

j

ob en

g

ineerin

g

process to ensure implemention when

confi

g

urin

g

the controllers.

(

See Application Step 6. Confi

g

ure

Controllers, for information on the various Excel 10

parameters and on Excel 10 point mappin

g

.

)

Step 2. Determine Other Bus Devices

Required

A maximum of 62 nodes can communicate on a sin

g

le

L

ON

W

ORKS

Bus se

g

ment. Each W7750

(

CVAHU

)

Controller

constitutes one node. If more nodes are re

q

uired, a Q7751A,B

Router is necessar

y

. Usin

g

a router allows up to 125 nodes,

divided between two L

ON

W

ORKS

Bus se

g

ments. The router

accounts for two of these nodes

(

one node on each side of the

router

)

; a Q7750A Excel 10 Zone Mana

g

er takes one node

and two nodes are available for operator terminal nodes,

leavin

g

120 nodes available for Excel 10 Controllers. All 120

controllers are able to talk to each other throu

g

h the router. A

Q7750A Excel 10 Zone Mana

g

er is re

q

uired to connect the

L

ON

W

ORKS

Bus to the standard EXCEL 5000

OPEN

S

y

stem C-Bus. Each Excel 10 Zone Mana

g

er supports up to

120 Excel 10 Controllers. This limit is set in the Excel 10 Zone

Mana

g

er database as an absolute maximum.

Step No. Description

1 Plan The S

y

stem

2 Determine Other Bus Devices Re

q

uired

3La

y

Out Communications and Power Wirin

g

4 Prepare Wirin

g

Dia

g

rams

5Order E

q

uipment

6Confi

g

ure Controllers

7 Troubleshootin

g

M15120A

NOTEBOOK PC

LONWORKS BUS

PORT

EIA-232

SERIAL

PORT

Q7752A

SLTA

CABLE

PART

NO. 205979

SHIELDED

INTERFACE

CABLE

EXCEL 10

W7750

CVAHU

CONTROLLER