8

Use the following guidelines to determine the actuator quantity and

torque requirements for your damper configuration.

Determine Damper Actuator Locations

Use the following configuration to determine the amount of

actuator locations your damper will require.

Single Section ≤ 48 x 74 D2, D3

≤ 60 x 74 D1

Dampers will never ship more than 2 sections wide and one

section high.

Configuration

A single section damper will have one actuator location.

A damper that is ≥ 48 x 74 ≤ 96 x 74 will have one actuator

location. This is a two section damper jackshafted together.

A damper that is ≥ 96 x 74 ≤ 144 x 74 will have two actuator

locations. This is a two section damper jackshafted together and a

single section damper.

Exception: 3 section wide ≤ 42 SFT damper will have one actuator

location.

If damper exceeds 74” height a second row is necessary. Apply

same logic above to each row of dampers.

For dampers larger than 144 x 144, please contact the Take-Off

Service (takeoff.service@honeywell.com) for a quote and actuator

location.

Mounting

Internal Mount: Blade drive lever bracket provided only. Customer

is responsible for providing mounting hardware.

External Mount: Actuator shaft will be provided as extension pin kit

to be mounted on side or with jackshaft pre-mounted on damper.

Damper And Actuator Sizing

Determining Damper Actuator Torque

Requirements

Use the following procedure to determine the required torque for

your damper.

NOTE: Damper area is measured using the H and W dimensions.

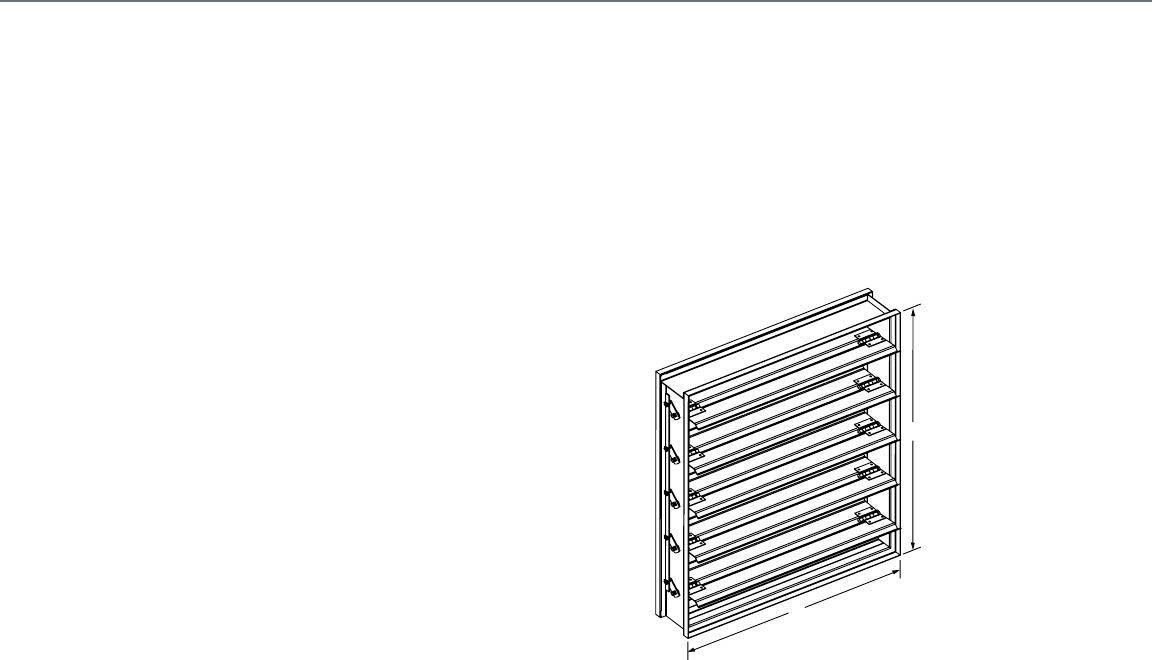

H

W

M20587

Measuring Damper Area

1. Calculate the damper area in square feet by multiplying the H

dimension by the W dimension.

2. Multiply the damper area by the lb-in. per square foot value

from Table 2 on page 9.

NOTE: The minimum lb-in. per square foot value that can

accommodate tight closeoff and no leakage applications is 5,

regardless of the value shown in the table.

3. Select the highest actuator torque value than the calculated

value.

EXAMPLE:

Low leakage, parallel blade damper:

H dimension = 48 in.

W dimension = 96 in.

Static pressure (in. w.c.) = 2 in. w.c.

Face Velocity = 1000 fpm

48 in. x 96 in. ÷ 144 = 32 sq. ft.

32 sq. ft. x 7 lb-in./sq. ft. = 244 lb-in.

where 7 lb-in./sq. ft = value from Table 2.

In this case you would need an actuator with a minimum nominal

torque of 224 lb-in.