244

Appendix A: Valve Selection and Sizing

Appendix A: Valve Selection and Sizing

Introduction

This section provides information on valve selection and sizing.

Valves must be selected for ability to meet temperature,

pressure, flow control characteristic, and piping connection

requirements of the hydronic system. Valve sizing is critical to

ensure support for heating and cooling loads with adequate

valve capacity, yet able to control system flow to provide stable

building conditions efficiently.

Definitions

Valve Components

Actuator:The part of an automatic control valve that moves the

stem based on an electric, electronic, or pneumatic

signal from a controller. The actuator and valve can be

two separate devices or together they can be one

device.

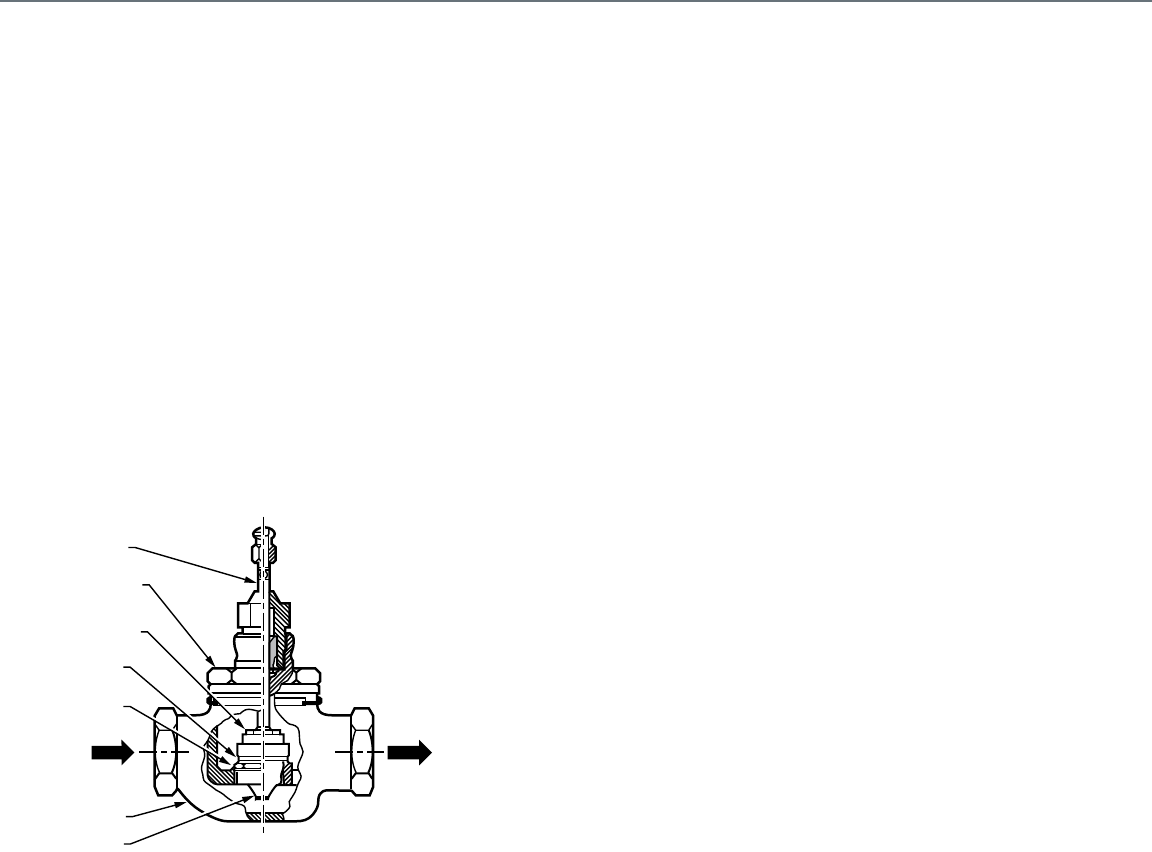

Body: The valve casting through which the controlled fluid

flows (Fig. 1).

Fig. 1. Globe Valve Components.

Bonnet: The part that screws to the top of the valve body and

contains the packing that seals and guides the valve

stem.

Disc: The part of the valve assembly that contacts the valve

seat to close off flow of the controlled fluid. Some valve

assemblies are built so the disc is replaceable.

Replaceable discs are usually made of a composition

material softer than metal. "Metal trim" valves use

precisely-machined metal plugs and seats operated by

high force actuators instead of a disk.

Plug: The part that varies the opening for the fluid to flow

through the valve body. The following describes the

three most common types of plugs:

— A contoured plug has a shaped end that is usually

end-guided at the top or bottom (or both) of the

valve body. The shaped end controls fluid flow

through the valve with respect to stem travel.

— A V-port plug has a cylinder, called a skirt, that

rides up and down in the valve seat ring. The skirt

guides the plug and varies the flow area with

respect to stem travel via its shaped openings.

— A quick-opening plug is flat and is either end-

guided or guided by wings riding in the valve seat

ring. The flat plug provides maximum flow soon

after it lifts from the valve seat.

Port: The opening in the valve seat.

Seat: The stationary part of the valve body that has a raised

lip to contact the valve disc when closing off flow of the

controlled fluid.

Stem: The shaft that runs through the valve bonnet and

connects an actuator to the valve plug.

Trim: All parts of the valve that contact the controlled fluid.

Trim includes the stem, packing, plug, disc, and seat; it

does not include the valve body.

Valve Flow Characteristics

Direction of Flow: The correct flow of the controlled fluid

through the valve is usually indicated on the valve

body. If the fluid flow through the valve is incorrect, the

disc can slam into the seat as it approaches the closed

position. The result is poor control, excessive valve

wear, and noisy operation. In addition, the actuator

must work harder to reopen the closed valve since it

must overcome the pressure exerted by the fluid on

top of the disc rather than have the fluid assist in

opening the valve by exerting pressure under the disc.

Gate and butterfly valves may offer bi-directional flow.

Equal percentage: A valve which changes flow by an equal

percentage (regardless of flow rate) for similar

movements in stem travel (at any point in the flow

range).

Linear: A valve which provides a flow-to-lift relationship that is

directly proportional. It provides equal flow changes for

equal lift changes, regardless of percentage of valve

opening.

Quick-opening: A valve which provides maximum possible

flow as soon as the stem lifts the disc from the valve

seat.

Valve flow characteristic: The relationship between the stem

travel of a valve, expressed in percent of travel, and

the fluid flow through the valve, expressed in percent

of full flow.

M12225

STEM

BONNET

SEAT

DISC

BODY

PLUG

DISC

HOLDER

OUT

IN