251

APPENDIX

Fig. 8. Linear vs. Nonlinear System Control.

QUICK-OPENING VALVE

A quick-opening two-way valve includes only a disc guide and a

flat or quick-opening plug. This type of valve is used for two

position control of steam. The pressure drop for a quick opening

two-way valve should be 10 to 20 percent of the piping system

pressure differential, leaving the other 80 to 90 percent for the

load and piping connections.Figure 9 shows the relationship of

flow versus stem travel for a quick-opening valve. To achieve 90

percent flow, the stem must open only 20 percent. Linear or

equal percentage valves can be used in lieu of quick-opening

valves in two-position control applications as the only significant

positions are full open and full closed.

Fig. 9. Flow vs. Stem Travel Characteristic of a Quick-

Opening Valve.

Linear Valve

A linear valve may include a V-port plug or a contoured plug.

This type of valve is used for proportional control of steam or

chilled water, or in applications that do not have wide load

variations. Typically in steam or chilled water applications,

changes in flow through the load (e.g., heat exchanger, coil)

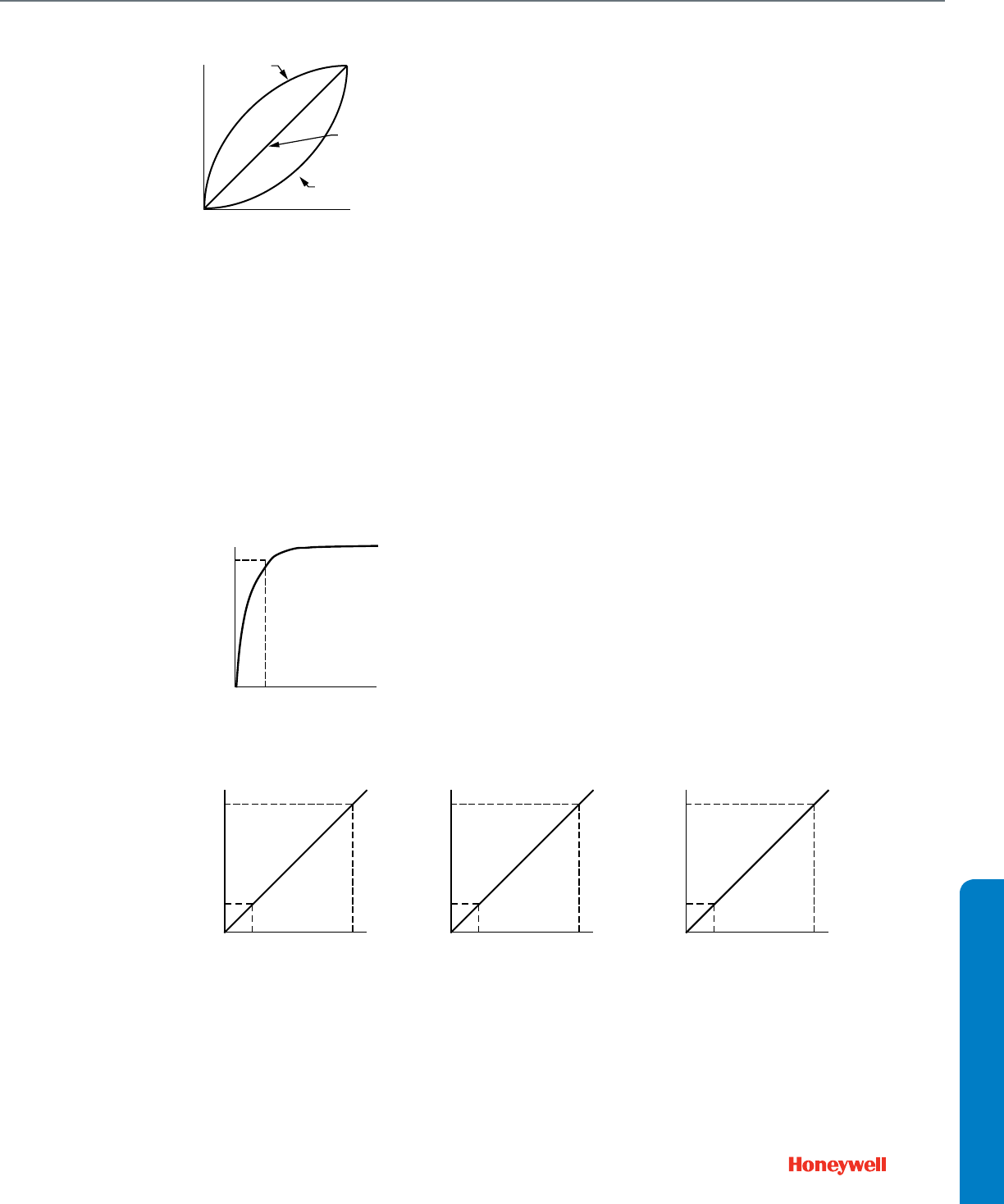

cause proportional changes in heat output. For example, Figure

10 shows the relationships between heat output, flow, and stem

travel given a steam heat exchanger and a linear valve as

follows:

— Graph A shows the linear relationship between heat output

and flow for the steam heat exchanger. Changes in heat

output vary directly with changes in the fluid flow.

— Graph B shows the linear relationship between flow and

stem travel for the linear control valve. Changes in stem

travel vary directly with changes in the fluid flow.

NOTE: As a linear valve just starts to open, a minimum

flow occurs due to clearances required to pre-

vent sticking of the valve. Some valves have a

modified linear characteristic to reduce this mini-

mum controllable flow. This modified character-

istic is similar to an equal percentage valve

characteristic for the first 5 to 10 percent of stem

lift and then follows a linear valve characteristic

for the remainder of the stem travel.

— Graph C shows the linear relationship between heat output

and stem travel for the combined heat exchanger and linear

valve. Changes in heat output are directly proportional to

changes in the stem travel.

Thus a linear valve is used in linear applications to provide

linear control.

Fig. 10. Heat Output, Flow, and Stem Travel Characteristics of a Linear Valve.

EQUAL PERCENTAGE VALVE

An equal percentage valve includes a contoured plug or

contoured V-port shaped so that similar movements in stem

travel at any point in the flow range change the existing flow an

equal percentage, regardless of flow rate. In mathematical

terms, this is an exponential response.

100%

0% 100%

NONLINEAR SYSTEM

RESPONSE

RESULTANT

LINEAR SYSTEM

CONTROL

EQUAL PERCENTAGE

CONTROL VALVE

TEMPERATURE

PERCENTAGE OF

FULL COOLING

C2330

100%

0% 100%

STEM TRAVEL

FLOW

C2331

90%

20%

QUICK-OPENING

CONTROL VALVE

C2332

100%

0% 100%

FLOW

HEAT OUTPUT

HEAT OUTPUT

90%

20%

90%

100%

0% 100%

STEM TRAVEL

FLOW

90%

20%

90%

100%

0% 100%

STEM TRAVEL

90%

20%

90%

GRAPH A

GRAPH B GRAPH C

20%

20%

20%

Appendix A: Valve Selection and Sizing