247

APPENDIX

Valve Types

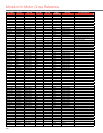

Ball valve:A ball valve has a precision ball between two seats

with a body (Fig. 3). Ball valves have several port sizes

for a give body size and go from closed to open with a

90 degree turn of the stem. They are available in both

two-way and three-way configurations. For HVAC

applications, ball valve construction includes brass

and cast iron bodies; stainless steel, chrome plated

brass, and cast iron balls; resilient seats with various

temperature ratings. Ball valves provide tight shut-off,

while full port models have low flow resistance, and

models with flow characterizing inserts can be

selected for modulating applications.

Fig. 3. Ball Valve.

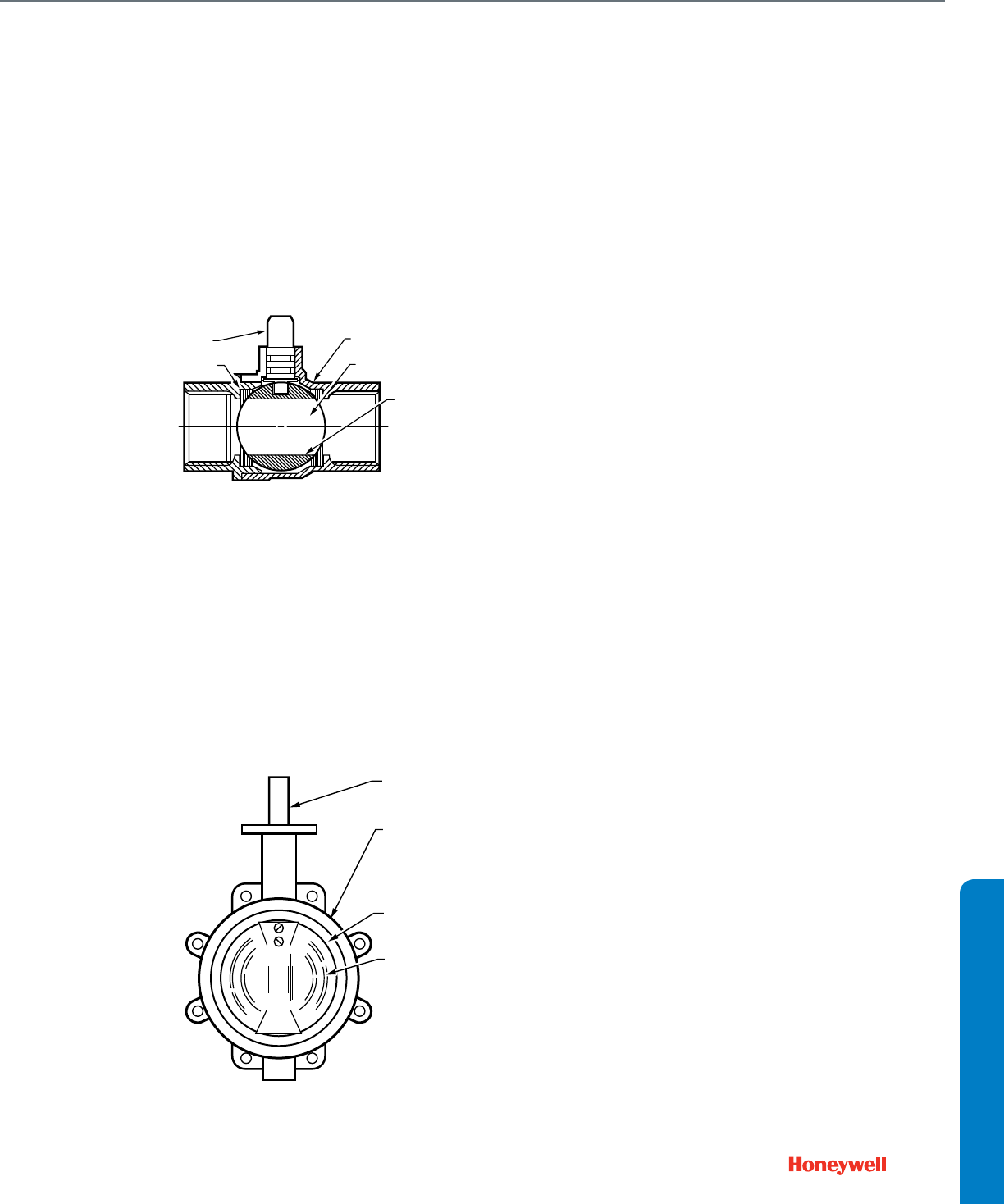

Butterfly valve: A valve with cylindrical bod, a shaft, and a

rotating disc (Fig. 4). The disc rotates 90 degrees from

open to closed. The disc seats against a resilient body

liner or spring-loaded metal seat and may be

manufactured for tight shut-off or made smaller for

reduced operating torque at lower close-off. Butterfly

valves have limited rangeability for modulating

applications so are used mainly for two-way operation.

For three-way applications, two butterfly valves are

assembled to a pipe tee with linkage for simultaneous

operation.

Fig. 4. Butterfly Valve.

Double-seated valve: A valve with two seats, plugs, and discs.

Double-seated valves are suitable for applications

where fluid pressure is too high to permit a single

seated valve to close. The discs in a double-seated

valve are arranged so that in the closed position there

is minimal fluid pressure forcing the stem toward the

open or closed position; the pressure on the discs is

essentially balanced. For a valve of given size and port

area, the double-seated valve requires less force to

operate than the single-seated valve so the double

seated valve can use a smaller actuator than a single

seated.

Also, double-seated valves often have a larger port

area for a given pipe size. A limitation of double-seated

valves is that they do not provide tight shut-off. Since

both discs rigidly connect together and changes in

fluid temperature can cause either the disc or the valve

body to expand or contract, one disc may seat before

the other and prevent the other disc from seating

tightly.

Flanged-end connections: A valve that connects to a pipe by

bolting a flange on the valve to a flange screwed onto

the pipe. Flanged connections are typically used on

large valves only.

Gate valve: A valve that controls flow using a gating

mechanism, usually a plate, that moves across the

valve seat instead of pushing against the flow. The

actuator works against the friction of the seals rather

than directly against the force of the water. Gate valves

are inherently self-sealing and are often capable of

high close-off pressures without an actuator. Ball

valves are a type of gate valve.

Globe valve: A valve which controls flow by moving a circular

disk against or away from a seat. When used in

throttling control a contoured plug (throttling plug)

extends from the center of circular disk through the

center of the seat for precise control (Fig. 1).

Pressure-balanced valve: A globe valve with a sealed

pressure chamber built into the plug, which equalizes

head pressure across the seat and allows most of the

actuator force to be used to close off the flow, resulting

in very high close-off ratings with very low seat

leakage.

Reduced-port valve: A valve with a capacity less than the

maximum for the valve body. Ball, butterfly, and smaller

globe valves are available with reduced ports to allow

correct sizing for good control.

STEM

BALL

BODY

PORT

SEATS

M12228

M12247

BODY

DISC

RESILIENT

SEAL

STEM

Appendix A: Valve Selection and Sizing