250

Ball Valve

Ball valves are available for two-position applications either

manual (hand) or power operated or for modulating applications

with direct coupled electric actuators. Ball valves are relatively

low cost, provide tight close off, and are available in two-way

and three-way configurations. As with all other valves, ball

valves must be properly sized to provide good flow control.

When used in modulating service, ball valves must be

specifically designed for modulating service as compared to

two-position service. Packing must provide leak-free sealing

through thousands of cycles to ensure trouble-free HVAC

service. The ball, stem and seals should be made of materials

that minimizes sticking and breakaway torque to achieve

smooth operation.

Two-way ball valves have equal percentage flow control

characteristics and flow in full-port models can be in either

direction.

Three-way ball valves can be used in either mixing or diverting

service. Full port models have linear flow control characteristics

for constant total flow. A popular option with 3-way valves is a

20% flow capacity reduction in the B port to equalize pressure

losses in a coil-bypass application.

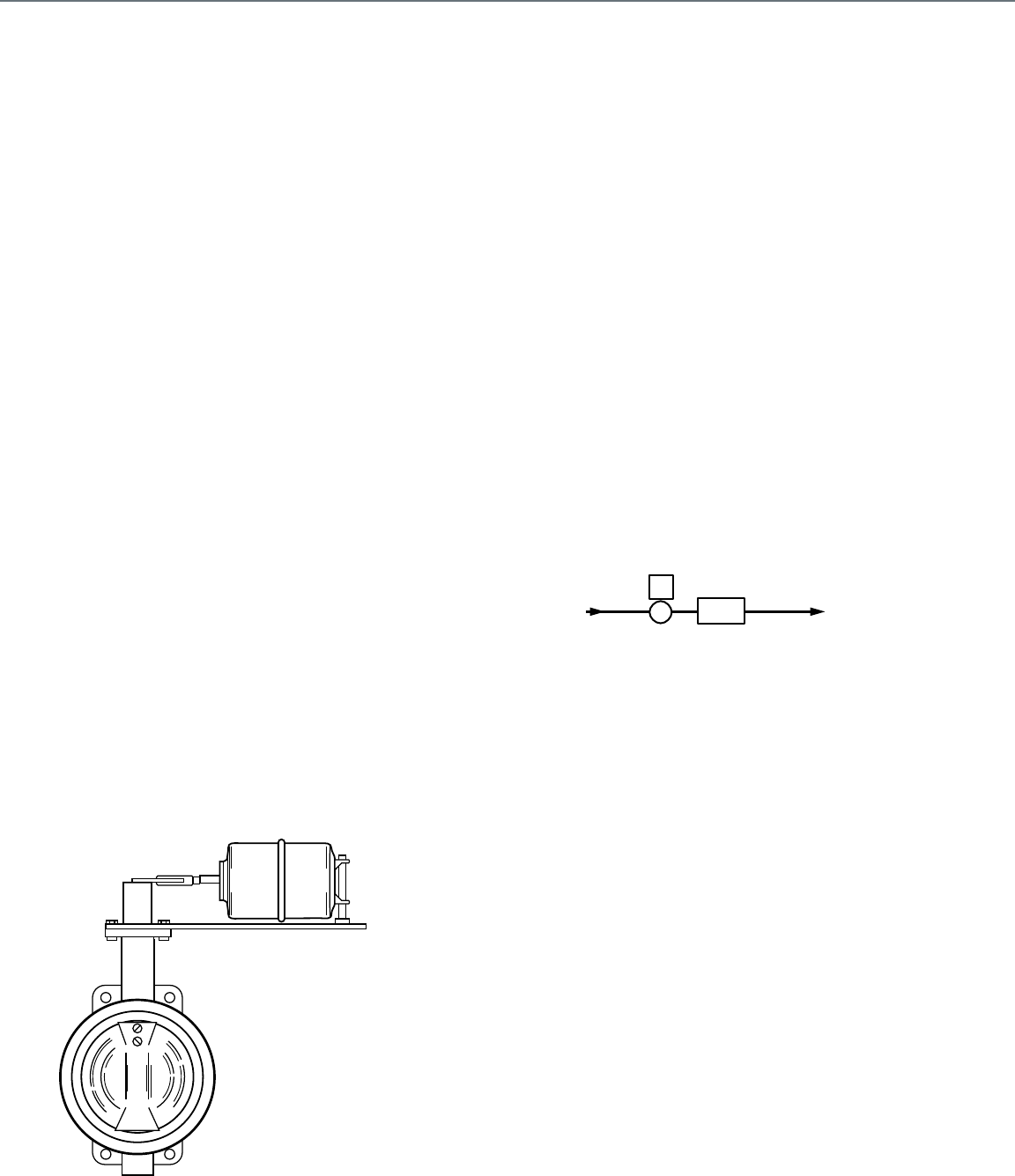

Butterfly Valve

Butterfly valves (Fig. 6) control the flow of hot, chilled, or

condenser water in two-position or proportional applications.

Butterfly valves are available in two-way or three-way

configurations. Tight shutoff may be achieved by proper

selection of actuator force and body lining. The three-way valve

can be used in mixing or diverting applications with the flow in

any direction. The three-way valve consists of two butterfly

valves that mount on a flanged cast iron tee and are linked to an

actuator which opens one valve as it closes the other. Minimum

combined capacity of both valves occurs at the half-open

position.

Fig. 6. Butterfly Valve.

When butterfly valves are used for proportional control, they

must be applied using conservative pressure drop criteria. If the

pressure drop approaches the critical pressure drop,

unbalanced forces on the disc can cause oscillations, poor

control, and/or damage to the linkage and actuator, even

though the critical flow point is not reached. Modulating control

is usually limited to a range of 15 to 65 degrees of disk rotation.

Butterfly valves are usually found in larger pipe sizes. For

example, two butterfly valves could be piped in a mixing

application to control the temperature of the water going back to

the condenser. The valves proportion the amount of tower water

and condenser water return that is flowing in the condenser

water supply line.

Two-way Valve

Two-way valves are available as globe, ball, or butterfly valves.

The combination of valve body and actuator (called valve

assembly) determines the valve stem position. Two-way valves

control steam or water in two-position or proportional

applications (Fig. 7). They provide tight shutoff and are

available with quick-opening, linear, or equal percentage flow

characteristics. Control valves are typically installed on the

supply side of convectors and radiators, and the return side of

small-bore water coils used in fan-forced equipment.

Fig. 7. Two-Way Valve Application.

Ideally, a control system has a linear response over its entire

operating range. The sensitivity of the control to a change in

temperature is then constant throughout the entire control

range. For example, a small increase in temperature provides a

small increase in cooling. A nonlinear system has varying

sensitivity. For example, a small increase in temperature can

provide a large increase in cooling in one part of the operating

range and a small increase in another part of the operating

range. To achieve linear control, the combined system

performance of the actuator, control valve, and load must be

linear. If the system is linear, a linear control valve is appropriate

(Fig. 8). If the system is not linear, a nonlinear control valve,

such as an equal percentage valve, is appropriate to balance

the system so that resultant performance is linear.

M10403

SUPPLY

LOAD

RETURN

C2329

TWO–WAY

VALVE

Appendix A: Valve Selection and Sizing