252

EXAMPLE:

When a valve with the stem at 30 percent of its total lift and

existing flow of 3.9 gpm (Table 2) opens an additional 10 per-

cent of its full travel, the flow measures 6.2 gpm or increases

60 percent. If the valve opens an additional 10 percent so

the stem is at 50 percent of its full travel, the flow increases

another 60 percent and is 9.9 gpm.

Table 2. Stem Position vs. Flow for Equal Percentage Valve.

An equal percentage valve is used for proportional control in hot

water applications and is useful in control applications where

wide load variations can occur. Typically in hot water

applications, large reductions in flow through the load (e.g., coil)

cause small reductions in heat output. An equal percentage

valve is used in these applications to achieve linear control. For

example, Figure 11 shows the heat output, flow, and stem travel

relationships for a hot water coil, with 200F, entering water and

50F entering air and an equal percentage valve, as follows:

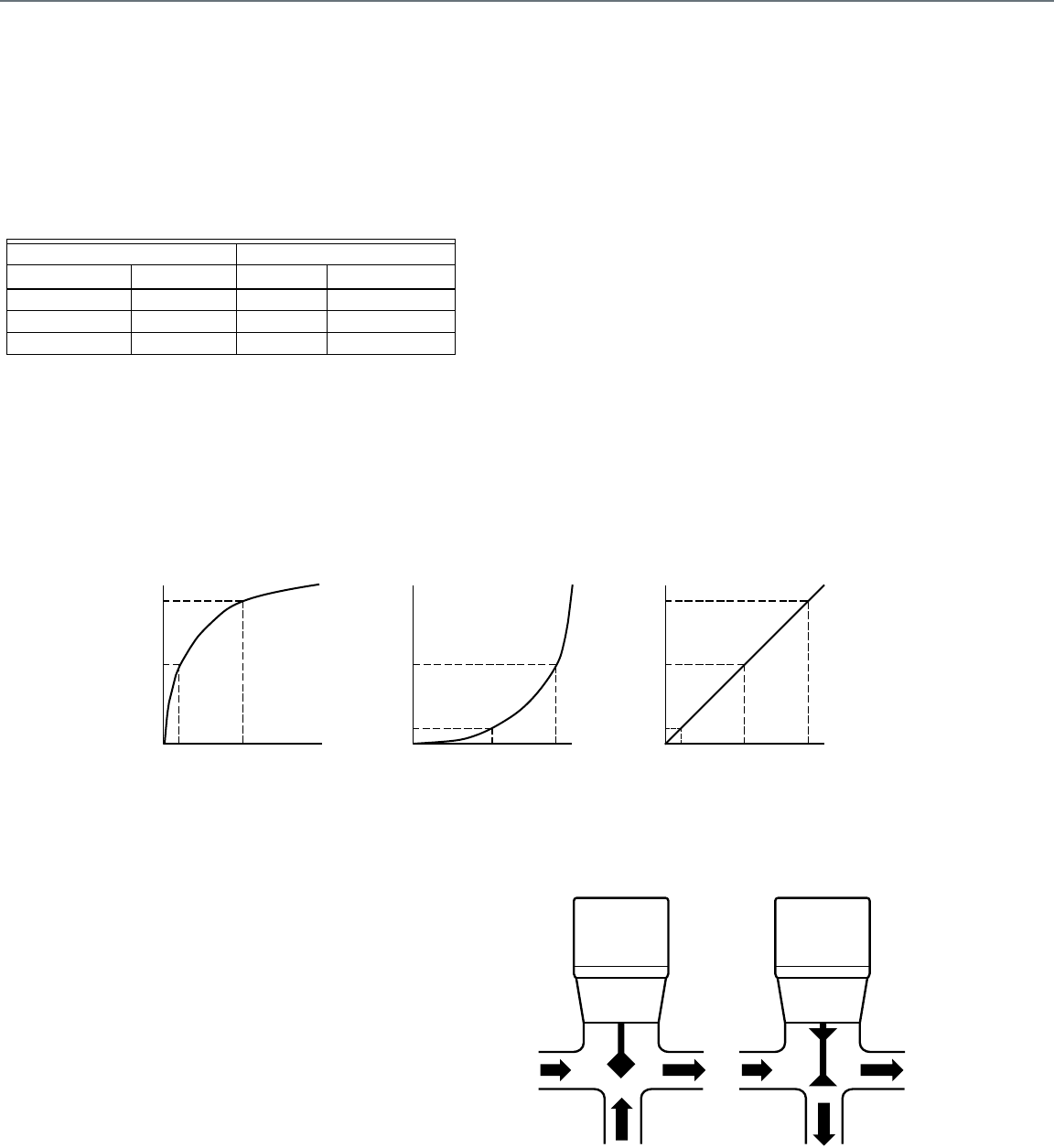

— Graph A shows the nonlinear relationship between heat

output and flow for the hot water coil. A 50 percent reduction

in flow causes a 10 percent reduction in heat output. To

reduce the heat output by 50 percent, the flow must

decrease 90 percent.

— Graph B shows the nonlinear relationship between flow and

stem travel for the equal percentage control valve. To reduce

the flow 50 percent, the stem must close 10 percent. If the

stem closes 50 percent, the flow reduces 90 percent.

— Graph C shows the relationship between heat output and

stem travel for the combined coil and equal percentage

valve. The combined relationship is close to linear. A 10

percent reduction in heat output requires the stem to close

10 percent, a 50 percent reduction in heat output requires

the stem to close 50 percent, and a 90 percent reduction in

heat output requires the stem to close 90 percent.

The equal percentage valve compensates for the

characteristics of a hot water application to provide a control

that is close to linear.

Fig. 11. Heat Output, Flow, and Stem Travel Characteristics of an Equal Percentage Valve.

Three-way Valves

Three-way valves (Fig. 12) control the flow of liquids in mixing or

diverting valve applications (Fig. 13). The internal design of a

three-way globe valve enables it to seat against the flow of

liquid in the different applications. An arrow cast on the valve

body indicates the proper direction of liquid flow. It is important

to connect three-way valve piping correctly or oscillations,

noise, and excessive valve wear can result. Three-way valves

are typically have linear flow characteristics, although, some are

equal percentage for flow through the coil with linear flow

characteristics for flow through the coil bypass. Ball valves are

also available in a three-way configuration, while two butterfly

valves can be made to act as a three-way valve.

Fig. 12. Three-Way Valves.

Stem Flow

Change Position Rate Change

— 30% open 3.9 gpm —

10% increase 40% open 6.2 gpm 60% increase

10% increase 50% open 9.9 gpm 60% increase

HEAT OUTPUT

HEAT OUTPUT

C2333

100%

0% 100%

FLOW

90%

10%

100%

0% 100%

STEM TRAVEL

FLOW

90%

100%

0% 100%

STEM TRAVEL

90%

10%

GRAPH A GRAPH B GRAPH C

50%

50%

50%

10%

50%

50%

50%

90%

10%

OUT

I

N

MIXING

VALVE

C2334A

DIVERTING

VALVE

IN

OUT

IN

O

U

T

Appendix A: Valve Selection and Sizing