249

APPENDIX

Valve Selection

Proper valve selection matches a valve to the control and

hydronic system physical requirements. First consider the

application requirements and then consider the valve

characteristics necessary to meet those requirements. The

following questions provide a guide to correct valve selection.

— What is the piping arrangement and size?

The piping arrangement indicates whether a two-way or

three-way mixing or diverting valve is needed. The piping

size gives some indication of whether the valve requires a

screwed end or a flanged end connection.

— Does the application require two-position control or

proportional control? Does the application require a normally

open or normally closed valve? Should the actuator be direct

acting or reverse acting?

In its state of rest, the valve is normally open or closed

depending on the load being controlled, the fluid being

controlled, and the system configuration.

For chilled water coils, it is usually preferable to close the

valve on fan shutdown to prevent excessive condensation

around the duct and coil, and to save pumping energy. This

may be accomplished with either normally closed valves or a

variety of other control schemes. Lower cost and more

powerful normally open valve assemblies may be used with

the close-on-shutdown feature and allow, in the case of

pneumatic systems, the capability to provide heating or

cooling in the event of air compressor failure.

Converter control valves should be normally closed and

outdoor air preheat valves should be normally open.

— Is tight shut-off necessary? What differential pressure does

the valve have to close against? How much actuator close-

off force is required?

Valves should never be allowed to "dead head" a pump

unless the pumps are controlled by variable speed drive

systems capable of detecting such conditions and shutting

down the pumps.

Single-seated valves provide tight shut-off, while double-

seated valves do not. Double seated valves are acceptable

for use in pressure bypass or in-line throttling applications.

The design and flow capacity of a valve determine who much

actuator force is required for a given close-off. Therefore, the

valve must first be sized, then, the valve and actuator

selected to provide the required close-off.

— What type of medium is being controlled? What are the

temperature and pressure ranges of the medium?

Valves must be compatible with system media composition,

maximum and minimum temperature, and maximum

pressure. The temperature and pressure of the medium

being controlled should not exceed the maximum

temperature and pressure ratings of the valve.

For applications such as chlorinated water or brine, select

valve materials to avoid corrosion.

— What is the pressure drop across the valve? Is the pressure

drop high enough?

The full open pressure drop across the valve must be high

enough to allow the valve to exercise control over its portion

of the hydronic system. However, the full open pressure drop

must not exceed the valves rating for quiet service and

normal life. Closed pressure drop must not exceed valve and

actuator close-off rating.

Globe Valve

Globe valves are popular for HVAC applications. They are

available in pipe sizes from 1/2 in. to 12 in. and in a large variety

of capacities, flow characteristics, and temperature and

pressure capabilities. They provide wide rangeability and tight

shutoff for excellent control over a broad range of conditions.

Globe valves are made in two-way, straight or angle

configurations and three-way mixing and diverting designs.

Globe valves close against the flow and have arrows on the

body indicating correct flow direction. Incorrect piping can result

in stem oscillations, noise, and high wear.

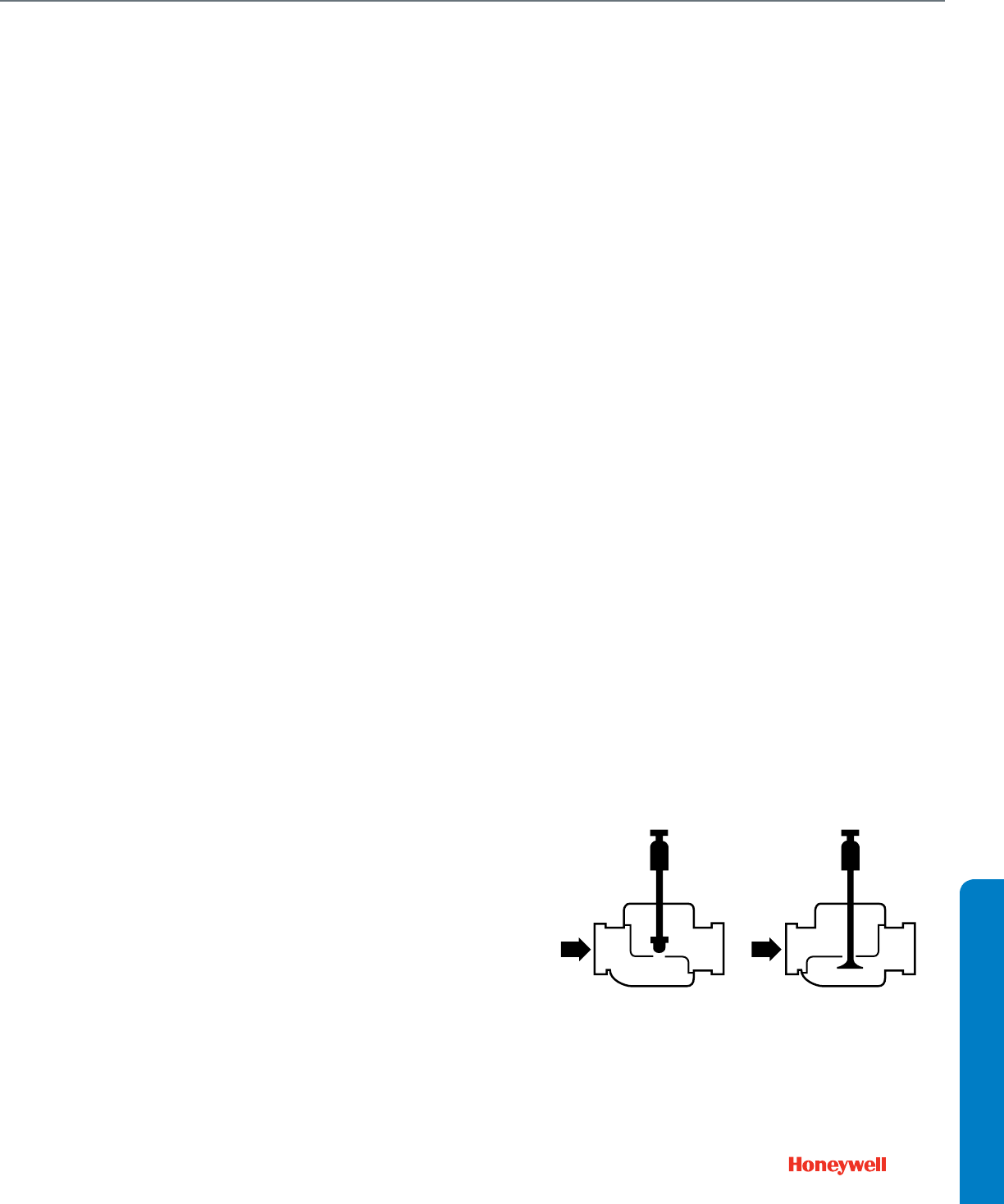

A two-way globe valve has one inlet port and one outlet port

(Fig. 5) in either a straight through or angle pattern. The valve

can be either push-down-to-close or push-down-to-open.

Pneumatic and electric actuators with linear motion to operate

globe valves are available for operation with many control

signals.

Fig. 5. Two-Way Globe Valves.

IN IN

PUSH-DOWN-TO-CLOSE

(DIRECT ACTING)

PUSH-DOWN-TO-OPEN

(REVERSE ACTING)

C2328A

Appendix A: Valve Selection and Sizing