A-9

After the trouble has been isolated to one of the feedback

loops, troubleshootin

g

can proceed as described in Tables A-

4, A-5, or A-6.

Series Re

g

ulatin

g

Feedback Loop. When troubleshootin

g

the series re

g

ulatin

g

loop, it is useful to open the loop since

measurements made an

y

where within a closed loop ma

y

appear abnormal. With a loop closed, it is ver

y

difficult to sep-

arate cause from effect. As described in Tables A-4 and A-5,

the conduction or cutoff capabilit

y

of each sta

g

e is checked

b

y

shortin

g

or openin

g

a previous sta

g

e, as follows:

1. Shortin

g

the emitter to collector of a transistor simu-

lates saturation, or the full ON condition.

2. Shortin

g

the emitter to base of a transistor cuts it off,

and simulates an open circuit between emitter and

collector.

Althou

g

h a lo

g

ical first choice mi

g

ht be to break the loop

somewhere near its mid-point, and then perform successive

subdividin

g

tests, it is more useful to trace the loop from the

series re

g

ulator backwards a sta

g

e at a time, since loop fail-

ures occur more often at the hi

g

her power levels.

Prere

g

ulator Feedback Loop. The prere

g

ulator feedback

loop (SCR control circuit) can be convenientl

y

checked usin

g

Table A-6. As indicated in Table A-6, the control circuit is

checked b

y

startin

g

with the waveform at point 7 and point 6

(shown on the schematic dia

g

ram) and tracin

g

forwards and

backwards from this point.

Overvolta

g

e Protection Circuit Troubles

When troubleshootin

g

the overvolta

g

e protection circuit, it is

useful to check the turn-on overshoot control circuit which

includes U20 and Q10. The function of the control circuit is to

slow down the risin

g

speed of the +15 V bias the moment the

power is turned on. This function prevents the suppl

y

from

false OVP trippin

g

the moment the power is turned on. After

the troubles has been isolated to overvolta

g

e protection cir-

cuit, troubleshootin

g

can proceed as described in Table A-7.

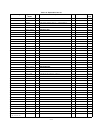

Table A-2. Reference and Bias Circuit Troubleshootin

g

METER

COMMON

METER

POSITIVE

NORMAL INDICATION NORMAL RIPPLE

(p-p)

PROBABLE CAUSE

TP6 point 2 +15.0 +/- 0.3 Vdc 2 mV Check U13, CR31, and CR32.

TP6 point 4 -12.0 +/- 0.3 Vdc 2 mV Check +15 V bias or U14.

TP6 TP7 +10.5 +/- 0.2 Vdc 2 mV Check +15 V bias, U11, and U14.

TP6 point 3 -5.1 +/- 0.5 Vdc 2 mV Check -12 V bias or VR1.

TP6 point 5 +5.0 +/- 0.3 Vdc 4 mV Check U1 and CR2.

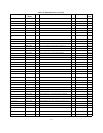

Table A-3. Overall Troubleshootin

g

SYMPTOM CHECKS AND PROBABLE CAUSES

Hi

g

h Output Volta

g

e a. Check series re

g

ulator feedback loop or prere

g

ulator feedback loop.

b. Refer to "Re

g

ulatin

g

Loop Troubles" para

g

raph or Table A-4 or A-6 as instructed.

Low and No Output Volta

g

e a. If output is zero, check fuse.

b. Check series re

g

ulator feedback loop or prere

g

ulator loop.

Refer to "Re

g

ulatin

g

Loop Troubles" para

g

raph or Table A-5 or A-6 as instructed.

c. Check CR20 shorted.

Hi

g

h Ripple a. Check operatin

g

setup for

g

round loops.

b. If output floatin

g

, connect 1 µF capacitor between output and

g

round.

c. Ensure that the suppl

y

is not crossin

g

over to constant current mode

under loaded conditions.

d. Check for low volta

g

e across C7 or Q1 and Q4.

e. Check for excessive ripple on reference volta

g

es (Table A-2).

Poor Line Re

g

ulation

(Constant Volta

g

e)

a. Check +10 V reference volta

g

e.

b. Check U9.