Error deadband

CNT-APG002-EN 19

®

Error deadband

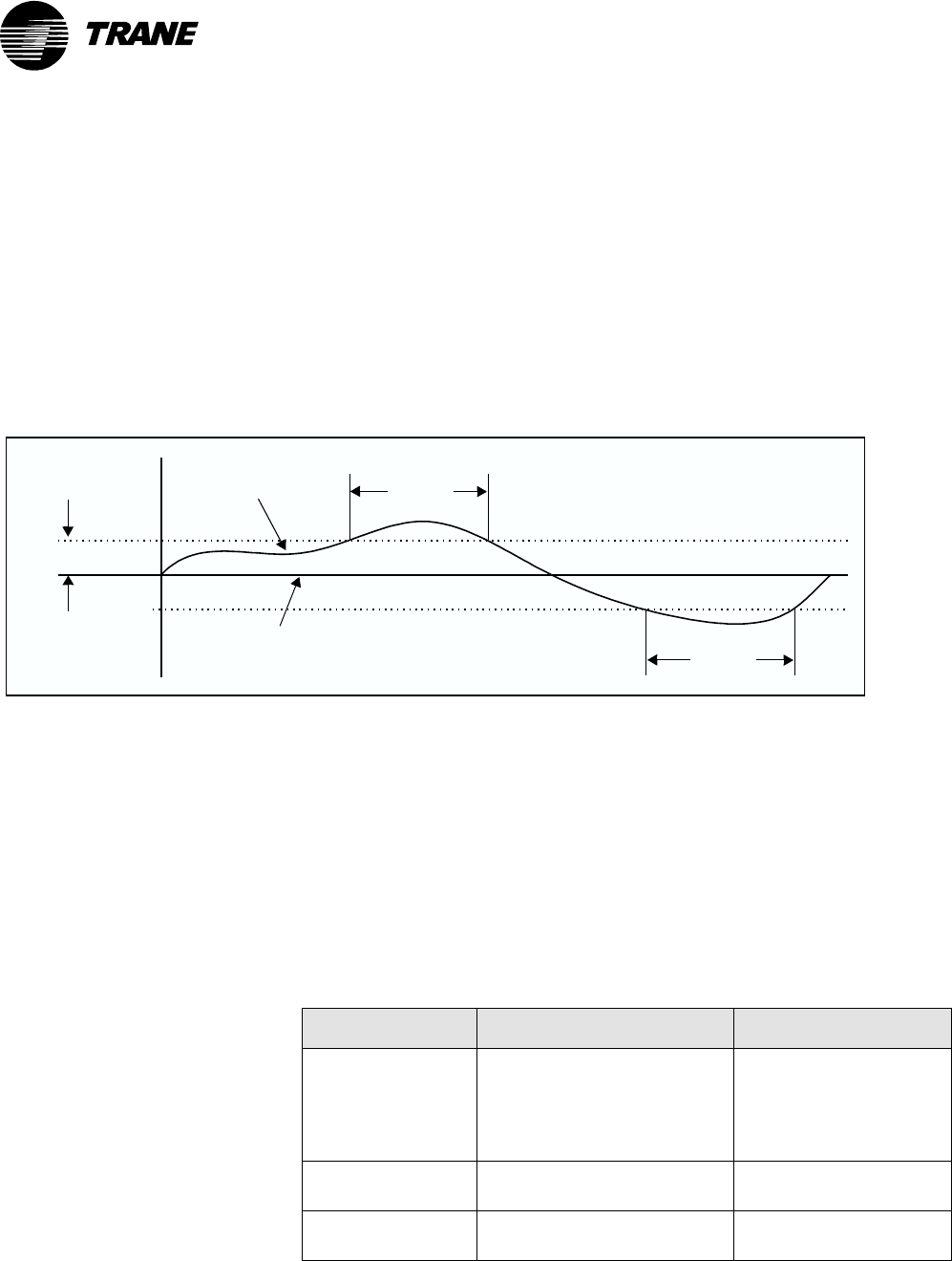

Error deadband is typically used to minimize actuator activity. It can also

be used to allow for some slack in system sensors and actuator mechanics.

Error deadband prevents the PID output from changing when the abso-

lute value of the error is less than the error deadband. For example, in

Figure 16 the error deadband is set at 2.0°F (1.1°C). As long as the abso-

lute value of the error is less than the 2.0°F (1.1°C), the PID output can-

not change. When the absolute value of the error exceeds 2.0°F(1.1°C),

the PID output can change.

Figure 16: Error deadband

Figure 16 illustrates the way that error deadband limits how often an

actuator is controlled. When a PID loop controls a chilled-water valve,

limiting control is not so important. But when a PID loop controls how

many stages of cooling are being used, it is important to limit equipment

cycling.

Typical applications

Table 4 shows reasonable error deadbands for several applications. The

error deadband can also be calculated as described in the following

sections.

control

control

Setpoint

Measured

variable

Error deadband

Error

Table 4: Error deadband settings

Application Suggested error deadband Notes

Modulating output

(analog or float-

ing point binary)

0.5°F (0.3°C) for temperature

0.01 in. wc (2.5 Pa) for duct

static pressure

1.0 in. wc (250 Pa) for build-

ing static pressure

Dependent on resolu-

tion of the measured-

variable sensor

Direct expansion

(DX) cooling

4.0°F (2.2°C) for temperature Staging application

Cooling towers—

fan staging

2.5°F (1.4°C) for temperature Staging application