60

11. ACCELERATOR & BRAKE

Before starting to work, ensure that the Power SW is OFF. Failure to observe

this can cause electric shock or short circuit.

Use care so as not to damage wirings. Damaged wiring can cause electric

shock or short circuit.

Do not touch undesignated places. Touching places not designated can cause

electric shock or short circuit.

This work should be performed by the Location's Maintenance Man or

Serviceman. Performing work by non-technical personnel can cause electric

shock hazard.

When performing work such as parts replacement other than those specified

in this manual, be sure to contact where you purchased the product from.

Confirm the work procedures and obtain precautions from where you

purchased the product from prior to performing work. Inappropriate parts

replacement and/or installation with erroneous adjustment can cause an

overload or the parts to come into contact, resulting in an electric shock, a

short circuit, and a fire.

If Accel. and Brake operation is not satisfactory, adjustment of Volume installation position or

Volume replacement is needed. Also, be sure to apply greasing to the gear mesh portion once

every 3 months.

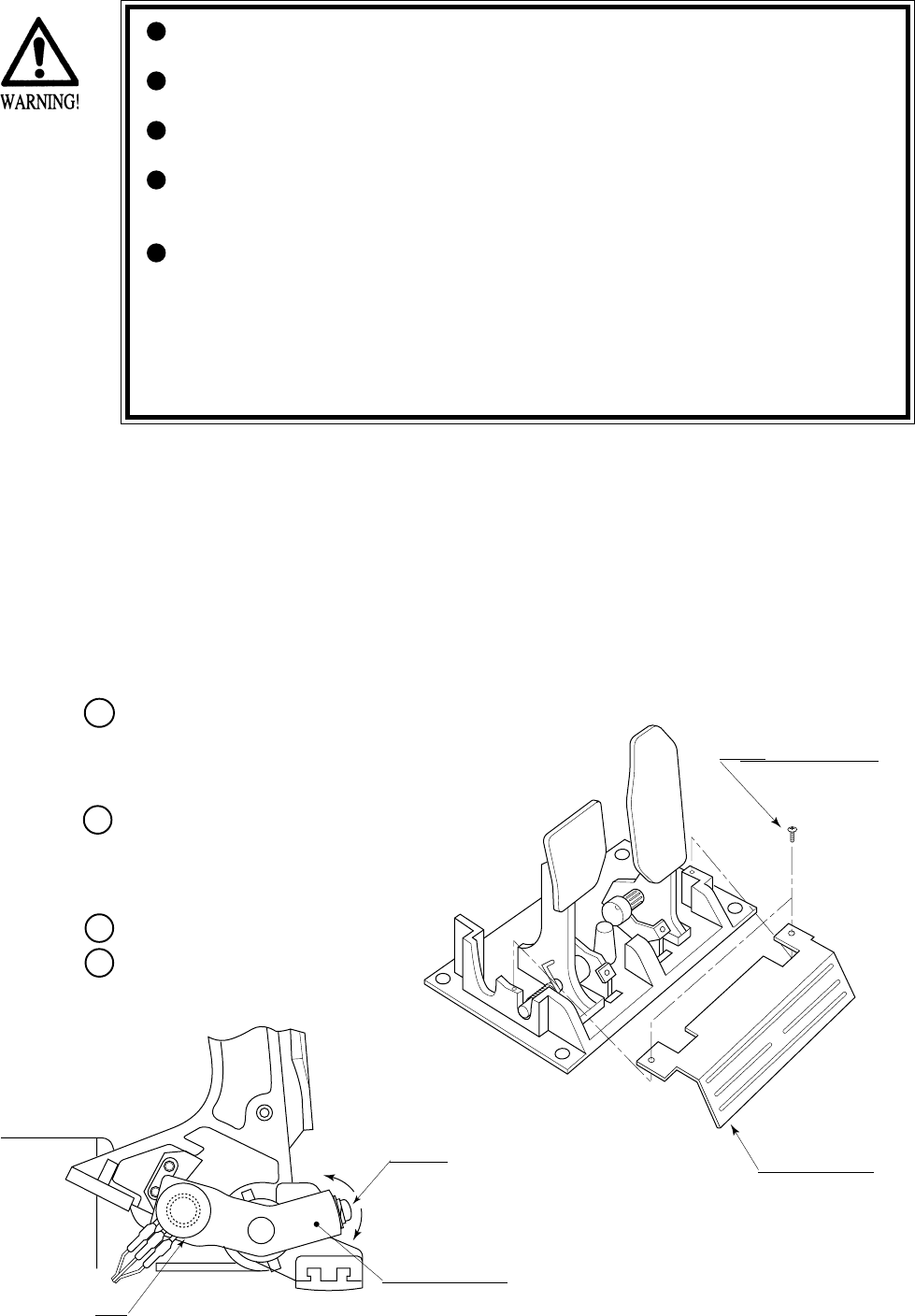

11 - 1 ADJUSTING AND REPLACING THE V.R.

The appropriate value for both ACCEL. Volume and Brake Volume is under 30H when released

and over C0H when stepped on. Check Volume values in the TEST mode. Since work is

performed inside the energized cabinet, be very careful so as not to touch undesignated places.

Touching places not specified can cause electric shock or short circuit.

Take out the 2 truss screws and

remove the Front Cover from the

Accel. & Brake Unit

(FIG. 11. 1 a).

Loosen the screw which secure the

Potentiobase, and adjust the

Volume value by moving the Base.

(FIG. 11. 1 b)

Secure the Potentiobase.

Perform Volume setting in the

Volume setting mode.

TRUSS SCREW (2)

M4 X 8, chrome

FRONT COVER

FIG. 11. 1 a

SCREW

M512,

w/flat & spring washers

POTENTIOBASE

V.R.

220-5484

220-5373

FIG. 11. 1 b

1

2

3

4