Description IW4/IW7 WB/WBV

2 D1 0412BA1-GB04

1.2.1 Vehicle with a Driven Axle

Drive the wheel axle to be tested onto the roller set. This will push both sensors rollers down

which measure the RPM of the wheels. Now both drive motors of the roller set will slowly

accelerated to nominal speed turning both vehicle wheels forward. When the drive motors have

reached nominal speed a comparison is made between the nominal drive roller speed and the

sensor roller speed in order to be able, at any time, to switch off the drive motors when a

slippage of 30% is exceeded. (This is to protect the drive motors against overload and the tires

against excessive wear.)

The READY indicator will light up, signaling that the test rig is ready to start the brake test.

During brake tests the vehicle is decelerated to a point, that at least one sensor roller exceeds

30% slippage and the drive motors are switched off.

1.2.2 4-Wheel Drive Vehicle

On non-permanent 4-wheel drive vehicles the brakes are tested with the 4-wheel drive switched

off, just like vehicles with only one drive axle.

Principle of 4 Wheel Drive

On 4-wheel drive vehicles the torque applied to the drive shaft is evenly distributed to all four

wheels, i.e. a quarter of the total torque will be applied to each wheel. The same applies for the

brake torques that arise when braking. When testing 4 wheel drive vehicles it must therefore be

ensured that no brake torque will be transferred from one vehicle wheel to the other. This is

accomplished if no torque is applied to the drive shaft of the differential during the brake test.

The following example will explain this in detail:

In order to simulate a defective brake, one brake is disabled. Now only one brake of the axle to

be tested is enabled. If the brake test is done on a standard test stand where the torque is not

eliminated from the drive shaft, the same force applies to the strain gauges of both drive motors,

i.e. the same brake torque will be indicated. This would lead to the false assumption that the

brakes are fully intact. If the test was conducted correctly, no brake torque would be indicated for

the wheel with the disabled brake and the actual brake torque applied to the other wheel would

appear.

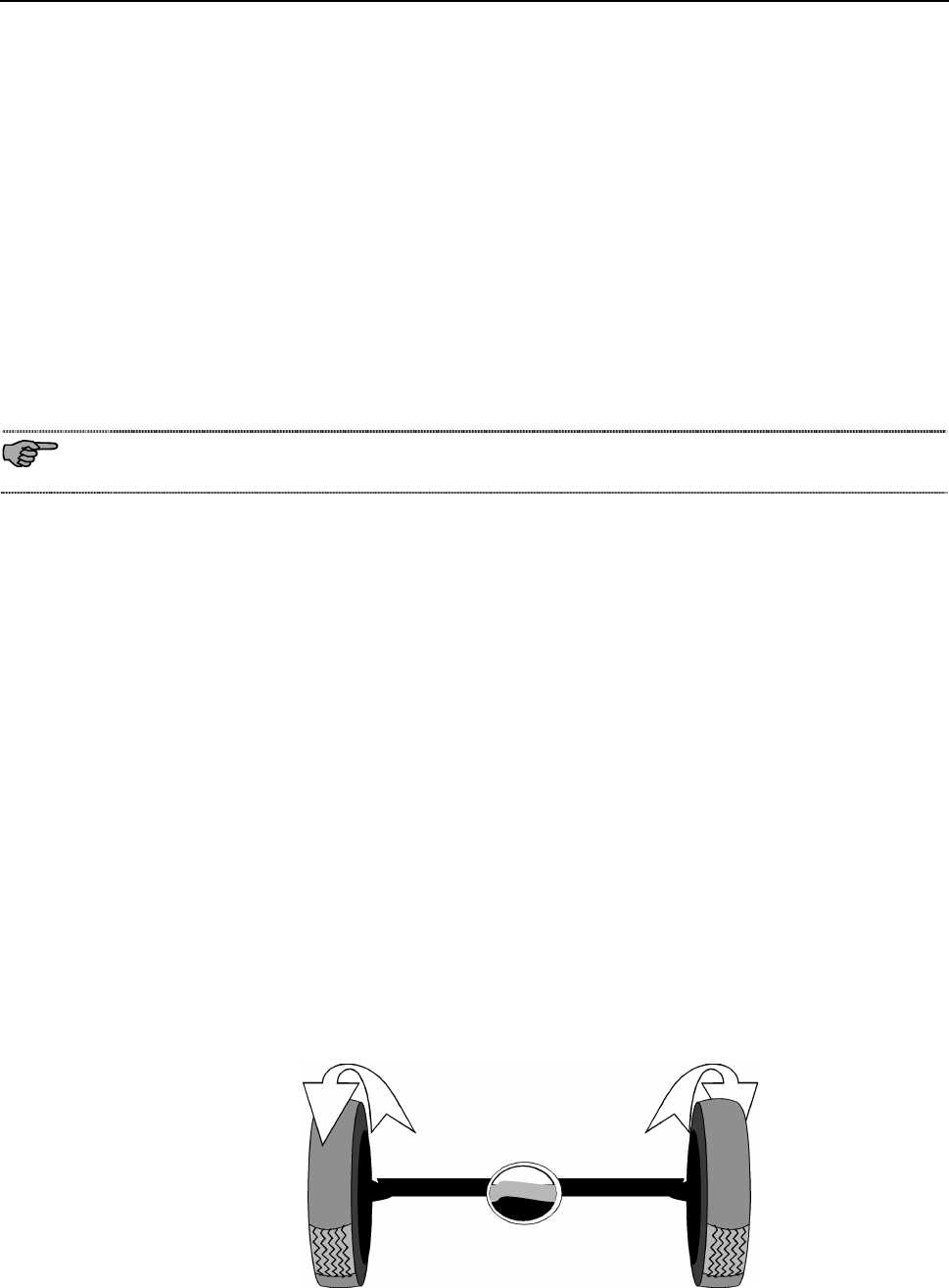

If both wheels of the axle to be tested are rotating forward during the brake test, the vehicle will

be lifted out of the test rig, as torque is transferred by the drive shaft to the wheels of the other

vehicle axle. To prevent this, the wheels counter rotate with the same RPM, one vehicle wheel is

driven in forward direction and the other wheel in reverse direction. This eliminates the torque

built-up in the differential against the drive shaft and transmission of torque to the other vehicle

axle.