16

POINT

(1) Use the thickest possible (max. 2 mm

2

(14 AWG)) wires for the

100/200 VAC and 24 VDC power cables. Be sure to twist these wires

starting at the connection terminals. To prevent a short-circuit should

any screws loosen, use solderless terminals with insulation sleeves.

(2) When the LG terminals and FG terminals are connected, be sure to

ground the wires. Do not connect the LG terminals and FG terminals

to anything other than ground. If LG terminals and FG terminals are

connected without grounding the wires, the PLC may be susceptible

to noise.

In addition, since the LG terminals have potential, the operator may

receive an electric shock when touching metal parts.

5.6 Connection Cable Wiring

• Do not bind connection cables with the main circuit (high voltage, heavy

current) or I/O signal cables, or lay them close to each other.

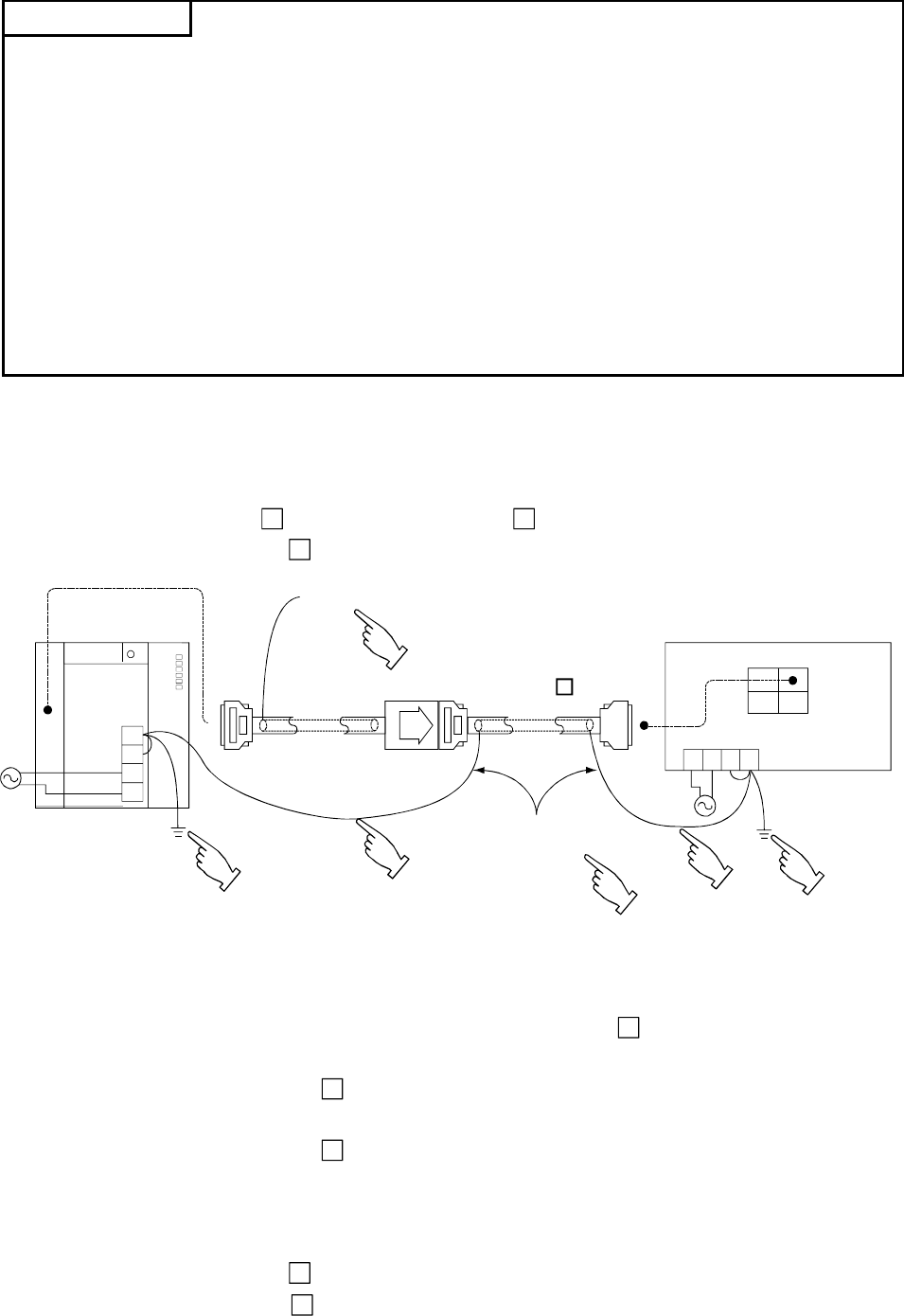

• When using A8GT-C

EXSS-1 or A8GT-C BS, ground wires as below.

(1) When using A8GT-C

EXSS-1 cable

FG

LG

N

L

PLC

Disconnected

(A8GT-EXCNB)

GOT

OUT

IN

FGLG

NL

2SQ wire FG terminal,

28 cm or less

(A8GT-C BS)

6)

5)

2)

4)

1)

3)

1) Connect the LG and FG terminals of GOT unit power to the ground

through the terminal block with one wire.

2) Use FG wires of 28 cm or less for the A8GT-C

BS cable.

3) Do not connect the FG grounding wire of A8GT-EXCNB cable.

4) Connect the A8GT-C

BS cable’s FG wire to FG of the GOT unit power

terminal block.

5) Connect the A8GT-C

BS cable’s FG wire on the PLC side to FG of the

PLC power supply module.

6) Connect the LG and FG terminals of the terminal block on the PLC to

ground with one wire.

(2) When using A8GT-C

BS cable

Connect the A8GT-C

BS cable

’

s FG wires on the both sides to the FG

terminals on the power terminal block of the both side GOTs.