18

Heating or

Cooling Control

Mode Operation

Heating or Cooling

Operation

For both single and dual compressor

operation, the ZN510 controller

cycles the compressor(s) on and off

to meet heating or cooling zone

demands. The controller uses the

unit capacity and pulse width

modulation (PWM) logic along with

minimum on/off timers to determine

the operation for compressor 1.

With a dual compressor unit, if the

desired conditions are not met by

controlling only the first

compressor, the controller runs

compressor 1 continuously and

controls compressor 2 according to

PWM logic along with the minimum

on/off timers. See Table 6 for heat

pump heating or cooling operation.

Certain heat pump configurations

may use one or two compressors for

cooling control. Heat pumps use

reversing valve control to switch

between heating and cooling. The

controller supports cooling only

configurations and heat pump

configurations.

For heat pump configurations, the

unit’s reversing valve is energized in

cooling and de-energized in heating.

For cooling, the reversing valve

output is energized simultaneously

with the compressor (compressor 1

in two compressor applications).

The reversing valve remains

energized until the controller turns

on the compressor for heating,

simultaneously de-energizing the

reversing valve. The reversing valve

only changes state when the

controller turns on compressor 1.

When a power failure occurs, the

reversing valve output defaults to

the heating (de-energized) state. To

reduce noise due to refrigeration

migration after compressor

shutdown, the controller does not

immediately operate the reversing

valve. The reversing valve changes

state only when the compressor

controls on, except when the

controller is in off mode.

For cooling only configurations, no

reversing valve is present and the

controller uses the compressor

stages for cooling.

Compressor Minimum

ON/OFF Timers

z When fan mode = OFF, Com-

pressor minimum

ON timers are

ignored.

z When fan mode = AUTO, Com-

pressor minimum

OFF timers are

observed.

z The diagnostic reset ignores the

compressor timers

ON and OFF.

z A communicated compressor

disabled or unoccupied signal

ignores minimum

ON times.

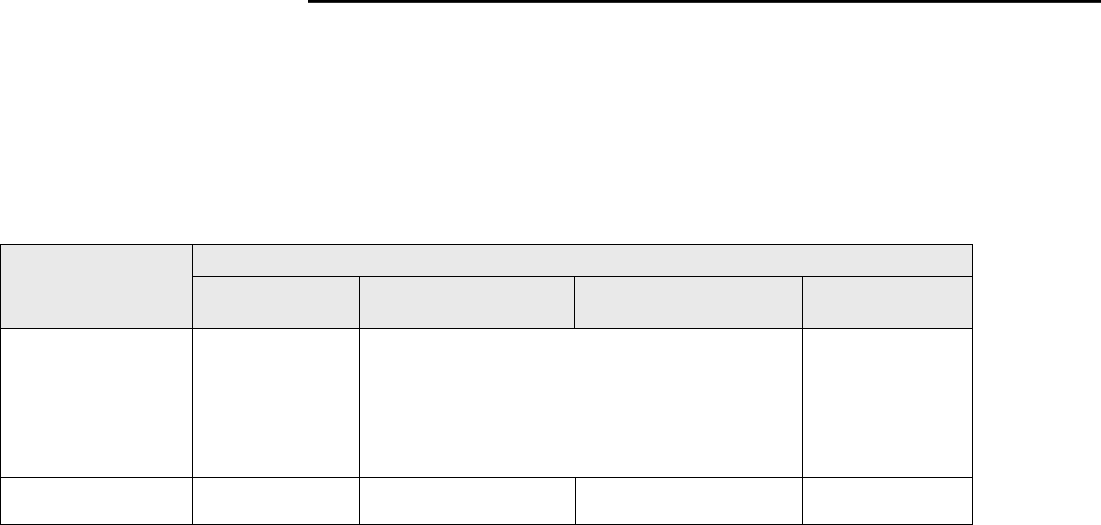

Table 7: Heat pump heating or cooling operation*

Unit

Capacity

0%

Between

0 and 50%

Between

50 and 100%

100%

Single compressor

Compressor

OFF

continuously.

Compressor output is controlled according to pulse width

modulation (PWM) logic between 0 and 100%. The

controller calculates the compressor on/off times based

on PWM logic and heating/cooling capacities. The

compressor is controlled on for longer periods as the

capacity increases and shorter periods as the capacity

decreases.

Compressor

ON

continuously.

Dual (Two) compressors

Both compressors

OFF continuously.

#1:

ON PWM.

#2:

OFF continuously.

#1:

ON continuously.

#2:

ON PWM.

Both compressors

ON

continuously.

*Note: No diagnostics present.