RV06 User Manual ◄ 13

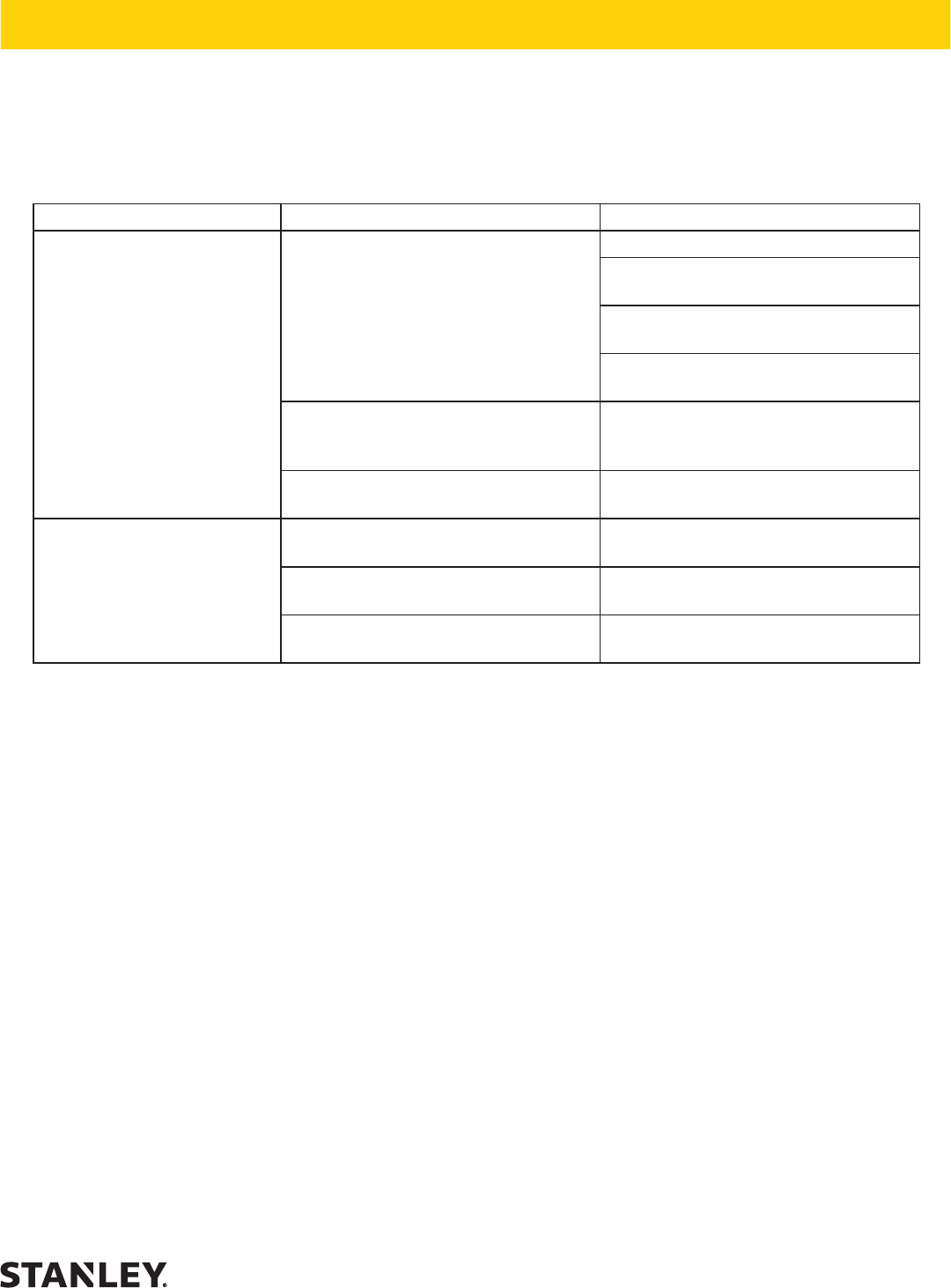

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the control valve, always check that the high-pressure hydraulic power

source is supplying the correct hydraulic ow and pressure to the control valve. Use a pressure gauge known to be

accurate. Check the ow with the hydraulic uid temperature at least 80 °F/27 °C.

Problem Cause Solution

Not automatically returning to

the NEUTRAL position.

Return or tank hose from control valve

to the intensier may be restricted

If hose is kinked, replace it.

If the hose has some obstruction in it,

clear the hose or replace it.

If hose coupler is obstructed, clean the

coupler or replace it.

Hose size may be too small for

application. Replace with larger hose.

If tool is equipped with an equalizing

valve, valve setting is lower than

control valve unloading valve setting.

Test and reset tool equalizing valve.

Dirt of debris causing push rod(s) to

bind.

Clean thoroughly.

Tool will not advance. High-pressure hydraulic system is not

providing ow.

Inspect high-pressure hydraulic system

for proper operation.

Control valve reverse plumbed to high-

pressure hydraulic system.

Check for proper connection.

Transfer disc installed 180° out of

correct position.

Inspect transfer disc installation and

correct it, if necessary.

TROUBLESHOOTING