10

Unit Operation

Low Temperature Detection

The low temperature detection

diagnostic protects the heat

exchanger by using an analog

leaving water temperature sensor to

protect refrigerant circuit 1 and a

binary low temperature detection

device to protect refrigerant circuit

2. Each individual refrigerant circuit

is disabled when the low

temperature condition exists for that

circuit.

For two compressor units, the

controller responds to low

temperature detection by allowing

the fan to operate, while disabling

the compressor for the faulty circuit.

The compressor for the normal

circuit continues to operate. The

outdoor air damper also operates

normally.

All unit operation is disabled when

the heat pump shuts down both

circuits, due to low temperature

conditions. See Table 3 for more

information.

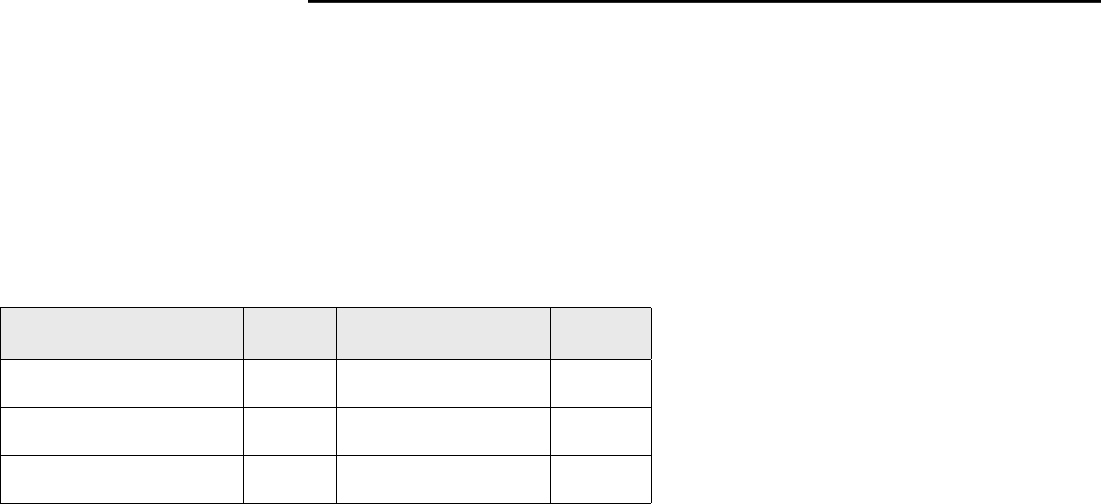

Table 3: ZN510 response to low temperature detection diagnostic

Description

Fan

Operation

Compressor Operation

Damper

Operation

Low Temperature Detection

(Circuit 1)

Enabled

Circuit 1-Disabled

Circuit 2-Normal Operation

Normal

operation

Low Temperature Detection

(Circuit 2)

Enabled

Circuit 1-Normal Operation

Circuit 2-Disabled

Normal

operation

Low Temperature Detection

(Circuits 1 and 2)

Disabled

Circuit 1-Disabled

Circuit 2-Disabled

Closed

Note:

z The low temperature detection device automatically resets when the heat exchanger temperature returns to

normal. However, you must manually reset the low temperature detection diagnostic to clear the diagnostic and

restart the unit. Refer to page 28 on how to reset a unit.

z If BOP 6 is configured as a generic binary output, the state of the output is not affected by the low temperature

detection diagnostic or by other diagnostics.

Condensate Overflow

A condensate overflow switch

detects the condensate condition.

The condensate overflow switch is a

normally closed device. This switch

is physically connected to the binary

input 2 (BI 2). When the

condensation reaches the trip point,

the binary input detects the

diagnostic condition. A condensate

overflow signal generates a

diagnostic which disables the fan,

disables all compressors, and closes

the 2-position outdoor air damper

(when present). The condensate

overflow diagnostic does not affect

the generic binary output (when

present).

Note:

The condensate overflow switch,

located in the condensate pan, auto-

matically resets when the conden-

sation returns to normal levels.

However, you must manually reset

the controller’s condensate over-

flow diagnostic to clear the diagnos-

tic and restart the unit. Refer to page

28 on how to reset a unit.

Occupancy

ZN510 uses the occupancy binary

input for two occupancy-related

functions. For standalone

controllers (any unit not receiving a

communicated occupancy request,

typically from a building automation

system), the occupancy binary input

determines the unit’s occupancy

based on the hardwired signal.

Typically, the signal is a dry set of

binary contacts which is either

connected to a switch or timeclock

contacts.

When a hardwired occupancy signal

is open, the unit switches to

occupied mode (if the occupancy

input is configured as normally

open). When a hardwired

occupancy signal is closed, the

controller switches to Unoccupied

mode.