A-3

a.Perform turn-on checkout procedure given in page 1-7.

b.Perform the CV and CC Load Regulation perfor-

mance tests given in the following paragraphs

respectively.

PERFORMANCE TESTS

The following paragraphs provide test procedures for verify-

ing the power supply's compliance with the specifications of

Table 1. Please refer to adjustment and calibration or trouble-

shooting procedure if you observe any out of specification

performance.

Measurement Techniques

Setup for All Tests.

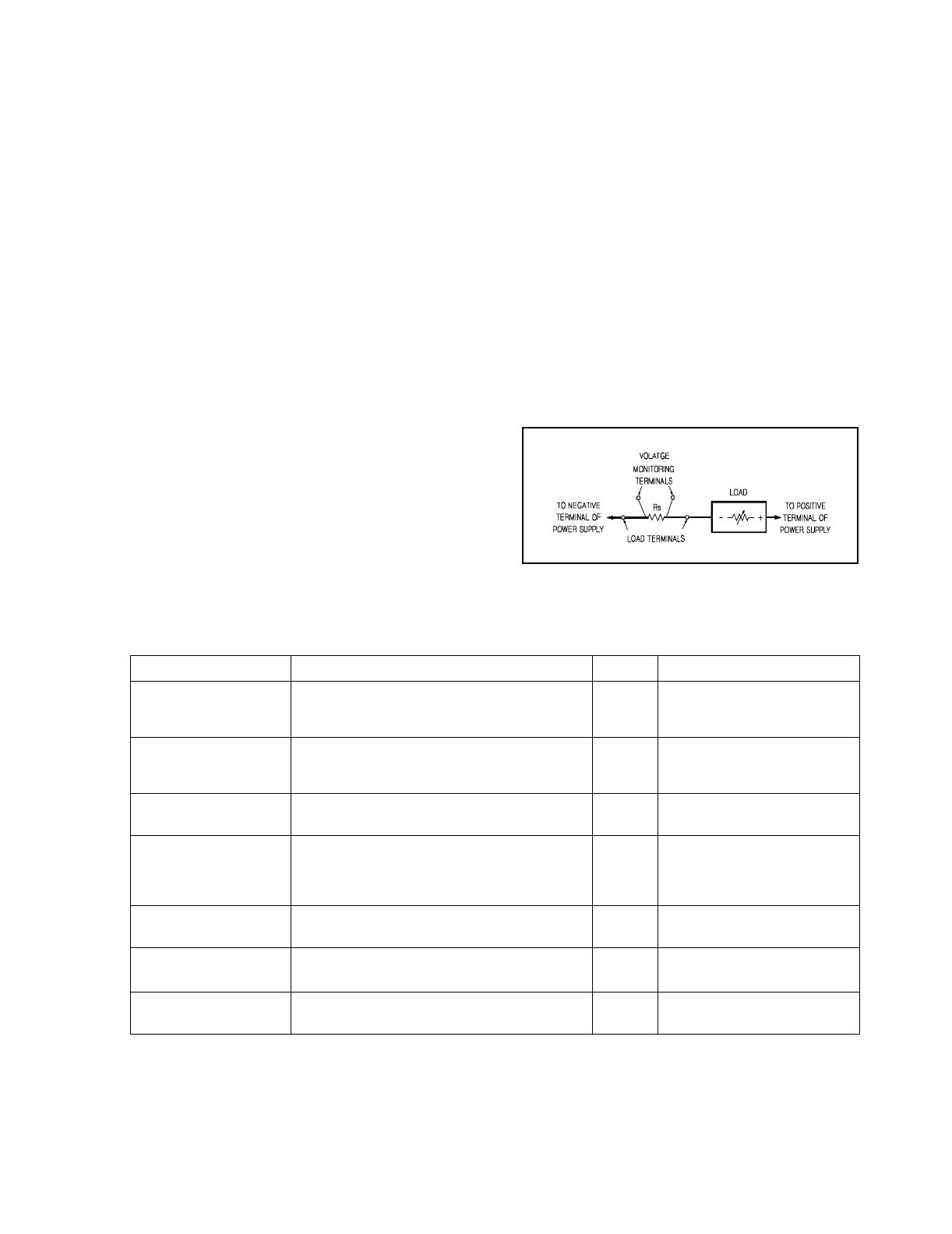

Measure the output voltage directly at the

+S and -S terminals on the rear panel; in this way the monitoring

device sees the same performance as the feedback amplifier

within the power supply. Failure to connect the monitoring device

to the proper points shown in Figure A-3 will result in the mea-

surement not of the power supply characteristics, but of the

power supply plus the resistance of the leads between its output

terminals and the point of connection.

Use separate leads to all measuring devices to avoid the sub-

tle mutual coupling effects that may occur between measur-

ing devices unless all are returned to the low impedance

terminals of the power supply. Twisted pairs or shielded cable

should be used to avoid pickup on the measuring leads.

Electronic Load.

The test and calibration procedures use an

electronic load to test the supply quickly and accurately. An

electronic load is considerably easier to use than load resis-

tor. It eliminates the need for connecting resistors or rheostats

in parallel to handle the power, it is much more stable than

carbon-pile load, and it makes easy work of switching

between load conditions as is required for the load regulation

and load transient response tests.

Current Monitoring Resistor Rs.

To eliminate output-current

measurement error caused by voltage drops in the leads and

connections, connect the current monitoring (sampling) resis-

tor between -OUT and the load as a four-terminal device. Fig-

ure A-3 shows correct connections. Connect the current

monitoring test leads inside the load lead connections directly

at the monitoring resistor element. Select a resistor with sta-

ble characteristics and lower temperature coefficient (see

Table A-1).

Figure A-3. Current Monitoring Resistor Connections

* P = Performance testing A = Calibration adjustments T = Troubleshooting.

Table A-1. Test Equipment Required

TYPE REQUIRED CHARACTERISTICS USE RECOMMENDED MODEL

Oscilloscope Sensitivity : 1 mV

Bandwidth : 20 MHz/100 MHz

Input : Differential, 50 ohm and 100 ohm

P, T Agilent 54600A

RMS Voltmeter True rms, 20 MHz bandwidth

Sensitivit

y : 1 mV

Accuracy : 5%

P

Multimeter Resolution : 100 nV

Accuracy : 0.0035%

P, A, T Agilent 34401A

Electronic Load Volta

ge Range : 240 Vdc

Current Range : 10 Adc

Open and short switches

Transient on/off

P Agilent 6063A

Load Resistor (R

L

) 1.3 ohm 60 W, 6.6 ohm 60 W, 20.5 ohm 60 W,

60 ohm 60 W

P

Current Monitoring

(Sampling) Resistor (R

S

)

0.1 ohm 0.1% 10 W, 1 ohm 1% 5 W P, A

Variable Volta

ge

Auto Transformer

Range : 85-130 and 200-260 Volts P, T